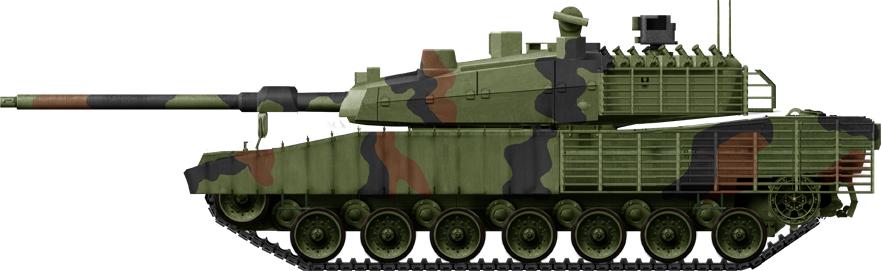

The Altay, first local Turkish Main Battle Tank

Although based on South Korean K2 Black Panther, and secheduled to produced by BMC under design assistance and technology transfer by Hyundai Rotem, the Altay is the very first main Battle Tank to be designed and produced in Turkey, unlike those currently in service, only updated, upgraded and modernized locally, notably by Aslan. The Altay constitutes a clearly advanced, 3/4th generation design, to constitute the bulk of the Turkish divisions over the next decades, with an expected service life well beyond 2050. It is a massive undertaking involving the BMC consortium made of ASELSAN, MKEK, ROKETSAN, HAVELSAN and Hyndai Military, which already have the interest of many customers, especially in the Middle East. The unit cost of USD $13.75 million as of today, which is on the high end of the spectrum.Development

Context in 1992

The Altay early genesis of development can be traced back in the early 1990s. It reflected a slight change of policy after the end of the cold war, with an inflexing traditional alignment towards the US grand strategy in the region, but still full participation in NATO. Turkey in 1992 still had the largest tank force of any NATO members, but started to seek out European equipments, after the refusal of the US to let Turkey acquire the M1A2 Abrams MBT. This was started already in 1983 with the acquisition of the German Leopard 1A3 (227), and its upgraded variant 1T (170) by Aselsan in 2002-2009. Next, 339 Lepoard 2A4 were bought from the German Bundeswehr in 2005, currently modernized by Aselsan and BMC as the "Leo2A4TR".The second line tank force is equipped with some 1,532 M60A3 Patton MBTs obtained from the US through the Conventional Forces in Europe Treaty, most being of the M60A3 TTS type (610) and modernized as the M60T (2008), M60TM (2017, 752) and 170 Sabra modernized in Israel. The third line is constituted by some 758 M48T, as Turkey had during the cold war the largest non-US M48 tank force in the world, with 3008 active models during the cold war. The current fleet comprised the A5T1 (400 in storage) and 358 A5T2 active.

It was clear at that point that having four types of main battle tanks and compoments, systems from four different countries made for a complicate maintenance and supply chain. The general staff also wanted to gain more autononomy in their procurement, to be freeier of their deployments (problematic with German tanks) or making exports of their subsystems. So having to develop a unique local MBT model presented many advantages, with in addition the benefit of possible exports. However in 1995 such undertaking was still far-fetched, despite the rapid development of a local, dynamic defense industry geared for export.

Official marketing leaflet, facebook

Context in 1994 program launch

The initial project became the "National Tank Production Project" programme in 1995 (Turkish: MİTÜP), an initiative to establish an independent and robust infrastructure for the development, production, and maintenance of the current main battle tanks of the Turkish Armed Forces, and under the impulsion of the the Undersecreteriat for Defense Industries, that a true "National Tank" would be the catalyst for diverses Turkish defense companies around a common goal. However designing such new MBT from scratch was clearly a massive undertaking. Therefore, the Turkish government seeked help from a foreign partner with already a suitable vehicle. A commission looked at the tanks on offer in 1995, and concluded the South Korean K2 Black Panther was the most advanced 3rd generation MBT at the time, while South Korea was open to such partnership.The K2 presented in conception from 1994 presented several advantages, notably it's commonality with the already Turkish owned and upgraded Leopard 2, the local powerpack derived from the German MTU-890 or the Rheinmetall gun, but the Korean licence was allowing exports which was not the case for the Leopard 2. The objectives of the South Korean Agency for Defense Development was preciselky to get rid of all foreign parts in order to reach true technological soveireignty, converging towards Turkish needs as well. Turkey had it's potential "proxy leopard".

The final tank design benefited from a much later agreement over a design assistance and transfer of technology by Hyundai Rotem. It took many years, until 2005, for this project to gain traction and years-long negociations with Rotem in Korea to reach a full agreement. In 2007, 30 March, an agreement was signed between Otokar and the Undersecretariat for Defense Industries of the Republic of Turkey in which the Committee awarded $500 million to Otokar for the full development and production of four prototypes.

On July 29, 2008, Turkey and Hyundai Rotem signed at last the ₩500 billion (US$540 M) design assistance and technology transfer contract: -Design assistance

-Technology transfer for system development

-Armor packages

-120 mm gun

In the loop was a Korean consortium with Hyundai Rotem as the lead, but also Hyundai Wia, and the Agency for Defense Development, which watched over the whole development process. The Ministry of Defense then allocated $1 billion for the full development of the Altay. In 2010, the crisis somewhat slowed down the development process, but the first 3D image of the MBT was presented on 7 April 2010, widely publicitzed into Turkish medias getting experts attentions around the world. It was accompanied by a press release by the Undersecreteriat for Defense Industries.

Development consortium (BMC)

Two years afterwards, Otokar's General Manager, Serdar Görgüç announced pre-studies for the development of a fully electric engine, but it was latter dropped.

Otokar headed a chain of contractors and sub-onctractors:

-The electronics company ASELSAN was tasked to create and and integrate the Volkan III modular fire control system, and its command & control, digital information systems.

-HAVELSAN as a subcontractor for the IFF and other electronic systems. -MKEK (Mechanical and Chemical Industries Corporation) is in charge of the development of the national MKE 120 mm tank gun

-Subcontractor Hyundai Wia for the Korean version of the Rheinmetall 120 mm main gun.

-ROKETSAN was chosen to produce a national armor package.

-Samyang Comtech in Poongsan for the tech transfer of the armor package technology, and performance test

-BMC Power as subcontractor for the MTU-inspired 1,500 hp power unit.

-Around 200 subcontractor under the direction of BMC replacing Otokar for the production and marketing/export phase (Otokar for the R&D)

This work at last culminated with the delvery of a fully-fledged first prototype Altay by late 2016. Other prototypes follows and are tested (ten in all) by Otokar in order for a separate order for the first lot of 250 tanks being prepared. A grang total of 1000 MBTs are now planned in four separate lots with additional upgrades for each along the way, with deliveries planned until 2045 or more. Koç Holding Vice Chairmain, and director Ali Koç from Otokar affirmed mass production was expected after a 18–22 months delay following the order's signing. The name of the tank, "Altay", was chosen to honor General Fahrettin Altay, which commanded the 5th Cavalry corps during the Turkish War of Independence in 1922.

Prototypes tree

- 2011: Mock-up of the Altay presented at IDEF 2011.

- 18 October 2012: First prototype trials, no side skirts, mock-up turret but MTU engine, Renk transmission.

- 16 November 2012 two prototypes passed initial acceptance tests

- 2014 two more prototypes delivered and tested

- 7 November 2016: Next four pre-production prototypes (Altay T2) deliverd for further acceptance tests in the Turkish Land Forces

- IDEF 2017: The Altay-AHT "urban operations tank" is showcased by Otokar in May, with a directional dozer blade.

- May 2019 last prototype demonstrator Altay T1 at IDEF 2019

- 2030: Altay T3, planned unmanned turret variant proposed for tests in 2024.

- Armored recovery vehicle project, planned future version, with 60 to be procured on converted T1 hulls.

- Mine clearing variant, 50 also to be procred, presumably on former T1 chassis. No date given but 2030 estimated.

- Leopard 2A4 with Altay turret. Announced and showcased in 2021 by BMC. However by 2021 German blocked the delivery of engine and transmission systems due to political issues. Still, Tirkey operates today some 300 ex-German Leopard 2A4 so this upgrade made sense for the next decade upgrade program.

Design

The Altay has externally many similarities with the Korean K2 and the Leopard 2 which the latter is partly based on. The chassis is very close to the K2, only extrenally differing by the choice of armour package, which changes a lot between various prototypes from 2016 to this day (2022). The Altay's main armament is a 120 mm 55 caliber (long caliber), a smoothbore gun which uses a static Muzzle Reference System. Protection relies on CBRN defense elements for a full collective NBC protection. Planned top speed was setup at 65 kph (40 mph) thanks to the BMC power 1,500 hp (1,100 kW) BATU V12 engine, but the upgrade program for later batches is planning an indigenous 1,800 hp engine.Hull

The chassis has the same dimensions and size as the K2, and weights about the same as a Leopard 2 (65 tonnes, or 72 short tons, 64 long tons), but is significantly heavier than the K2 (55 tons). It is shorter at 7.3 metres (24 ft) long for the hull only and 10.3 metres (34 ft) with the gun forward (versus 7.5 and 10.8 m on K2), but significantly larger with a width of 3.9 metres (13 ft) versus 3.6 (11 ft 10 in) and taller at 2.6 metres (8.5 ft) versus 2.4 (7 ft 10 in) for the K2.The rest of the hull design is totally standard, with a front compartment for the driver which seats at the center, with a left-sliding hatch dotted with three sight periscopes, one forward infrared. There is a centrak combat compartment with the turret basket, extra stored ammunition below, then the engine compartrment at the rear. Both are fitted with automatic fire extinguishers.

Mobility

The beating heart of the Altay is its BMC power BATU V12 rated for 1,500 hp (nominal), the final agreement being awared to the Korean Doosan Infracore Co. and S&T Dynamics Co., for final production engine and transmission in 2012. The first batch was scheduled in 2017 to be powered by a 1,500 hp diesel MTU MT 883 Ka501 diesel coupled with a Renk transmission. The next 1800 hp power unit was to be 100% national. The current production batch is powered by Doosan Infracore/S&T Dynamics DV27K engine, coupled with an EST15K transmissions to Turkey for the Altay as confirmed in 2021. Indeed Germany forbade the export of the MTU.The drivetrain comprises seven roadsheels as the K2/Leopard, with compatible twin ruberrized roadsheels, three return rollers per side. Idler are at the front, drive sprocket at the rear. The single pin track is standard among NATO tanks, with rubber pads. They rest on torsion bars, with hydraulic arms

The Altay is able to reach 70 km/h governed, with a range estimated to around 500 km. Field tests figures are not all available ans based on similar MBTs. The Altay is noramlly capable of managing a 60% Gradient, a 30% Side slope, cross a one meter Vertical step, 2.8 m trench, for 1.2 m without preparation and up to 4.1 m with preparation.

Protection

Passive protection

The Altay's standard armor figures are unknown, probably close to the K2/Leopard 2A5 figures. The composition of the armor package, made by Roketsan are unknown an classified. Common figures given are around 900 mm to 1900 mm of RHA equivalent. The modular turret armor at the frontal arc and sides was tailored to defeat tandem HEAT charges, and current APFSDS rounds. The sides skirts benefits from the an explosive reactive armor kit and internal layers for the front glacis. it is provided with ERA bricks and NERA addons. The 2017-2019 versions are fitted with BAR (cage) at the rear of the hull and turret armor to defeat RPGs in urban environment. There is also a collective NBC system with overpressure.Active protection

The rear of the tank turret hosts two series of eight automatic smoke dischargers, manually reloaded.There is a sensor mast aft and a laser barrel adjuster for automatic corrections and a first warning system in case of laser hit, or incoming threats to launch smoke charges.

Armament

The tank uses an advanced computerised Volkan-III modular fire control system, in alternative to the National Cannon Fire Control System for Naval Platforms (TAKS). Developed by Aselsan, in partnership with STM, software division of SSM.As standard, both the gunner and the commander are provided with stabilised day/thermal sights incorporated, with a laser range-finder and hunter-killer capability. The commander can fire idependently is the gunner is impaired.

Main: 120 mm/L55 MKEK smoothbore

Developed by MKEK, national arsenal, and state-owned ammunition producer Makine ve Kimya Endustrisi Kurumu (MKE). It is fitted with a muzzle reference system, thermal sleeve and fume extractor. The ammunition is stowed in the turret bustle, with blow out panels on the roof as now standard on 3rd gen MBTs. The remainder are stored above the chassis on suspended, insulated caissons under the turret basket, so below the fighting compartment floor.Secondary: Modular RWS + coax

The seondary armament is a 12.7mm heavy machine gun mounted on the right of the turret for commander operation, in a semi-remote, or fully remote weapons systems. It sis modular enough to accept KPVT machine guns as well, possible also to operate a standard M48 grenade launcher. Control is operated by cameras in the turret; it fires tracers, HE and AP rounds belt-fed.The tank also mounts a coaxial 7.62mm machine gun, right of the main armament. It is belt-fed, with around 5000 rounds in store, including tracers.

Current status: Incoming production

Turkish Order

The Altay won the Turkish army contract, estimated at $3.5B and signed on 9 November 2018 for a batch of 250 tanks so far. Three more similar batches are expected in the near future, on the T2 and possiblt T3 standard, with upgrades for T1 FY2040-2050.The Qatari Order

Qatar has purchased 100 Altay tanks in 2021, along with an estimated 20 T-155 Firtina SPH. All should be of the T1 standard.Other potential customers

The Emirati Army had declared its interest for the Altay, but so far no demonstration had been made nor specs issued. Other middle-east customers should be interested as well, notably Syria and Libya.Links & resources

Equipments lists, ground forcesmilitary-today.com

army-technology.com

Article on armyrecognition.com

On raillynews.com

On fortuneturkey.com

On nationalinterest.org

About the BATU power unit

Turkish M60T fitted with Aselsan PULAT APS Active Protection System (Aselsan)

dailysabah.com

On yellowstarmagazine.com

On AA.com

The urbcomb package HST at haberturk.com

Article on www.dunya.com

specifications | |

| Dimensions | 7.3/10.3 oa x 3.9 x 2.6 m (34 x 13 x 8.5 ft) |

| Total weight, battle ready | 65 tons (72 ST, 64 LT) |

| Crew | 4 (driver, Cdt, gunner, loader) |

| Propulsion | BMC BATU V12 TD 1500 hp |

| Suspension | 4x4 independent helical coil springs |

| Speed (road) | 65 km/h (40 mph) |

| Range | 450 km (280 mi) |

| Armament | See notes |

| Armor | Classified Composite Modules & active protection |

| Total production | 10 prototypes, 250 awaited 2023 |

Modern Tanks

Modern MBTs posters

Denel Bagder (2018)

Type 16 MCV (2016)

Gepard 1A2 last rounds 2011

SANDF

Russian AFVs

Main Battle Tanks