United States of America (1942-1945)

United States of America (1942-1945)

Walking Pillbox – None Built

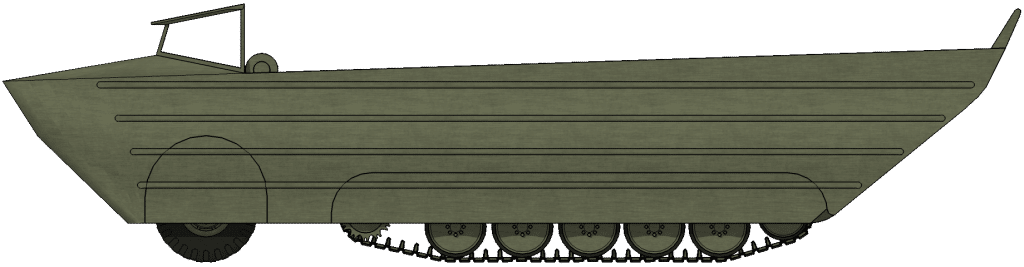

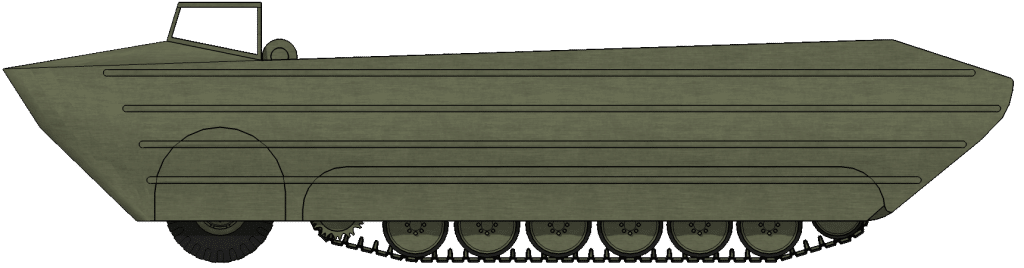

If someone tried to define the term ‘tank’ as a military vehicle, they generally would agree on the need for a turret, armor, and tracks. Whilst there are exceptions to each of these to one degree or another, the only real unifying point across definitions is the use of armor and this raises interesting possibilities, especially for Henry Wallace of Freeport, New York, USA. In 1942, Henry Wallace expanded the idea of what a tank can be to a vehicle with no tracks at all. In fact, Wallace did not even go for wheels for some wheeled tank/armored car, nor did he go the full way towards a legged machine. Instead, Wallace went for perhaps the most unusual method of transportation possible, a vehicle that walked on one leg, pushing what could be named as a tank to a new extreme.

The Man

The patent for this odd design came from Henry W. Wallace of Freeport, New York State, USA. He should not be confused with the US Secretary of State for Agriculture of the time with the same name. Freeport, New York, is not a large city but, as of 1940, there were just over twenty thousand people living there according to US Census Data. The only other patent from this man was filed in October 1940 and was for a flexible pen in the shape of a snake wrapped around the wrist. With a relatively common name and few other details to go off, there is insufficient information to be able to reliably identify the designer at this time.

Concept

There are inherent problems in a tank design that involve compromises. Whether operating on wheels or tracks, movement is limited to the direction the vehicle faces and a change in direction involves turning or reversing. Protection for the vehicle is concentrated forwards to protect from fire from the front, as it would be too heavy and impractical to add equivalent protection to the sides and especially to the rear. Thus, a conventionally laid out combat vehicle is more vulnerable from the sides and rear than the front. Any turning or change in direction by the vehicle might expose that weakness to an enemy. A vehicle on which all sides are equally armored does not have to worry about the direction of an enemy attack or even turn to face it.

The same is true for armament. With a vehicle carrying a turret armament, it has to be turned to target a specific threat, and, once more, the maximum of protection faces the enemy threat. Armor protection, as both weight and bulk have to be shared between the turret and hull, provides a challenge for a designer as to where to use the armor for optimal value.

With those two primary considerations in mind, the conventional vehicle cannot deliver equal protection and firepower all round – for Wallace, the solution was effectively a simple one. Create a vehicle that was symmetrical in defensive capabilities and offensive alike, and this meant a circular body. This body would make the tank especially valuable in a defensive situation, where it could simply ‘sit’ as a bunker to guard or control an area and then, when the job was done, move on.

The propulsion of such a vehicle could not rely upon tracks or wheels, as it would not be able to change direction quickly enough in the mind of Wallace. Instead, he opted for a single leg which was located in the center of the doughnut-shaped machine. With this, he felt, the tank would be able to “oscillate” to move, with all-round gun positions guaranteeing that firepower constantly faced the enemy. Thus, the vehicle could advance, retreat or move sideways without regard to enemy position or flanking attacks.

Layout

With a doughnut-shaped body resembling a pressure cooker or saucepan with a lid, the machine was certainly odd. The ‘handle’ of the lid was a small cabin that could be rotated in any direction and in which sat the driver of the machine, with a view slit for observation.

Source: US Patent US2371368

The rest of the machine was circular, with 6 gun positions located at 60 degrees from each other. Each position had a field of fire of up to 45 degrees to each side, which managed to create small blindspots immediately alongside the vehicle between the guns.

Source: Modified from US Patent US2371368 by Author

The smooth exterior of the vehicle was broken up by the 6 gun positions, but there would be no sign of the propulsion leg from the outside when the vehicle was ‘sat’ down as a pillbox. The leg itself resided in an octagonal area within the floor of the tank, with its gearing and hydraulic actuators around it to control its position and direction. The extension of the leg, however, was not done hydraulically but using compressed air or, as suggested by Wallace, by means of an explosive expansion of gas. This might have seemed like a good idea for a patent application, but was utterly preposterous for even this rather silly design. The automotive power was to come from a two-stroke fuel-injected diesel engine of an unspecified type. In a lengthy explanation of how the whole system was meant to work, Wallace explained that this explosive method was to work by releasing fuel into the top of the hollow extensible cylinders which formed the leg and that, with a single detonation of a cartridge into this cylinder, the explosive gases from this detonation would rapidly propel the vehicle upwards to get out of trouble or leap into action. Quite what effect this bounding kangaroo leap would have on the occupants is not explained and perhaps was never even considered as a possible issue or concern.

Source: US Patent US2371368. Note this image has been digitally cleaned by the author.

Source: US Patent US2371368. Source: US Patent US2371368

The rest of the internal arrangement within the machine was relatively straightforward. Between the outer walls, with those 6 gun positions, was a raised fighting platform under which ran a lot of the mechanical equipment (such as pumps) to run the machine. The outer skin of the machine was supported at the top and bottom by supporting beams. Despite the size of the machine and the number of men within it, just one hatch is shown in the patent drawing, in the rotating cabin for the driver at the top.

In terms of crew, even assuming just one man per gun (x 6), a driver, and a commander would mean not less than 8 men to reasonably crew this vehicle.

Propulsion

Whilst there have been designs for walking machines before, they usually relied upon continual support by their legs even when not in motion. More than that, they also had to depend on at least 2 legs for bipedal stability or more in motion. Wallace eschewed such ideas or any concept of motion short of brachiation from nature and went instead for a system using one leg. It is obviously not possible to walk on one leg without a hopping motion, but the design did not produce some giant pogo stick type of movement. It instead had an unusual undulating step where the second ‘foot’ would be the vehicle itself.

Consisting of a giant doughnut shape, with the single leg occupying the central recess in the bottom, at rest, the vehicle sat on the ground as a giant round fort or pillbox. During this phase, the leg could move forwards to a position in the direction of movement and then lift the whole vehicle off the ground, bringing it upwards and in the direction of travel. Now having moved a short distance ahead or in any direction, the leg would collapse slowly bringing the vehicle back to rest on the ground. The process would then repeat for as long as may be needed to move from location A to B. At all times whilst sitting on the ground, the leg was completely enclosed by the body and the vehicle provided both maximum firepower and maximum protection in all dimensions simultaneously. Using four large wheels, one on each side of the leg, and an element of rotation within the housing for it, the leg could be prepositioned in any direction in anticipation of a move that would be unknown to anyone outside the machine by observing it.

There are, however, serious problems with this method of motion, not least of which are ground pressure, balance, and speed.

Firstly, with the entire weight of the vehicle concentrated onto just a single point of contact with the ground. As the leg extended hydraulically into the ground to raise the body, it would sink into anything other than a good hard surface. The result would potentially be the leg impaling the ground to an extent that it might not be easily removed. This would be the military equivalent of trying to walk on a beach in high heels. If this sinking happened when the body was off the ground, the result could be disastrous, as moving a point of balance beyond the lip of the foot would result in the machine flailing over.

This brings up the second point of balance. Not only could the machine potentially tip if the ground shifted or leg sank when moving, but this would be magnified as a problem moving on anything other than a flat surface. Whilst the foot itself had a semi-flexible coupling in the manner of an ‘ankle’ connecting it to the base of the leg, the foot allowed for a limited degree of flexibility. Measurements of the vehicle would indicate that it would become unstable past 10 degrees of any slope. This would render the vehicle unable to operate on anything other than ideal flat terrain. Wallace sought to correct this rather obvious deficiency with his idea by stating that it was to use a gyroscopic stabilization device located around the center of gravity and consisting of two oppositional gyroscopes.

The final major problem with the practicalities of the mean of motion for the vehicle is speed. Movement in the chosen direction is limited by the amount of movement available to the foot at the point when the body of the vehicle is on the ground. Moving the foot in the desired direction whilst on the ground (1), as the hydraulics push on the foot, the body gradually lifts off the ground and is righted to a new forward position (2) until reaching full height (3). The tank can remain at any elevation between ground level and (3) for combat, although this would expose the leg to enemy fire. Return to the ground starts from the elevated position (4) down vertically (5) to the new resting position (6), a short distance from point (1). To continue the motion, the leg is moved to the new forward position (7) and the vehicle rises (8) to a new elevation (9) and so on.

One step beyond this slow move-lift-lower means of motion, Wallace drew an even more fanciful one. Here, the leg would do far more than even those rather absurd methods of movement, showing the tank literally jumping.

Source: US2371368

This slow move-lift-lower process could be sped up to a ‘dragging’ speed whereby only enough pressure need be applied to the foot to raise the body from the ground far enough that the hydraulics for the leg movement could drag it forwards and then return to the body to rest as the foot moves again. It is surely this method that would have been the only practical way of moving the vehicle, although practical is not really applicable to such an implausible design.

Source: Author

Wallace made no mention or estimate of the speed of this system of propulsion, but it was clearly not possible to combine a rapid bounding from the machine with a chance of the crew being in a fighting condition, even assuming the system had worked. The easiest, simplest, safest form of motion, the dragging method, would perhaps at best manage walking pace on a good surface.

Armor

As with many other features of this vehicle, little information can be discerned on which to judge the level of protection provided. No information is provided other than to say that protection was implied as being equal in all directions. From the approximate scale of the vehicle, the size of the seat, and space for the crew, the drawing would appear to indicate armor would have to have been metal (presumably steel) and not much more than bulletproof in thickness.

Armament

With 6 evenly distributed guns around the outside, it is unclear what sort of firepower Wallace had in mind. An enemy could be engaged at best by just two of the guns at any one time, leaving ⅔ of the firepower idle. Wallace could simply have had a rotating turret with a single large gun or multiple gun mountings, which would have obviated the need for so many crew and guns. Instead, unless the vehicle was totally surrounded, then all of the firepower could never be used at the same time and none of it when moving.

Conclusion

Weakly protected for a static pillbox, poorly protected for such a visible tank, and oddly armored for a fighting vehicle, the design was particularly bad when it came to motion. The single-leg concept, as drawn, was preposterous and unlikely to work even on a flat and hard surface, let alone a modest slope or wet ground. There, this tank would display the mobility of a lawn dart when moving and a house brick at other times, with less potential than either.

What Wallace was trying to secure as intellectual property with this design is clearly the single springing leg concept and a tank of equal protection and firepower. What he actually designed was perhaps one of the least practical, workable, or sensible systems of vehicular motion imaginable.

Trying to imagine what possible use this vehicle might have had to the US military or Allies in 1942, when it was submitted, is even less clear. Today, it can be seen as just one of those ideas from a well-meaning public eager to engage in and/or profit from the war by producing war-winning weapons and ideas. Sadly for Wallace, this was not one of them.

Sources

US Patent US2371368 Vehicle, filed 16th October 1942, granted 13th March 1945

US Patent US2266942 Bracelet, field 24th October 1940, granted 23rd December 1941

US Decennial Census data https://www.census.gov/programs-surveys/decennial-census.html

Colonel Allison Ridley Williams (1891-1966). Photo: Nashvillekit via findagrave.com

Colonel Allison Ridley Williams (1891-1966). Photo: Nashvillekit via findagrave.com