Italian Republic (1992-1993)

Italian Republic (1992-1993)

Self-Propelled Anti-Aircraft Gun – Design Only

The M42 ‘Duster’ was an open-topped self-propelled anti-aircraft gun (SPAAG) based on the hull of the M41 Walker Bulldog light tank. Beginning as a design in 1951, the M42, using the twin 40 mm Bofors M19A1 guns, soon became the standard SPAAG for the US Army. Starting life as the T141 and designed by Cadillac Motors, the first prototype was ready in late 1951 and was pushed into production. Standardized in October 1953, the vehicle remained in production in the US at the Cleveland Tank Plant until June 1956 and at ACF Industries, Berwick, Pennsylvania until December 1953. A total of 3,700 were produced. The M42 (upgraded to the M42A1 standard) remained in US service until 1969 when it was replaced with the Vulcan air defense system, although some were still in National Guard service until 1991.

Even using this early Cold War era chassis, the vehicle was seen to have some value as a light, cheap, and available platform. As a result, in 1992, the Italian firm of Breda was looking at the vehicle as a basis for a new light air defense system still based around the 40 mm Bofors but with a new turret and features.

The Upgrade

In 1992, the Italian firm Breda Meccanica Bresciana based in Milan offered a new and cheap light air defense vehicle based on this surplus M42A1 platform. This was not aimed at the Italian market, as Italy did not operate the M42A1 for air defense, even though it did operate some vehicles which used the same chassis. Countries that did use the M42A1 at the time included Austria, Greece, Guatemala, Jordan, Lebanon, Taiwan, Thailand, Tunisia, Turkey, and Venezuela. Many of these countries had received their M42s via post-reunification German vehicle stockpiles. Unfortunately, there is no information as to which country the upgrade was aimed at or if it was just a general upgrade on open international offer. Certainly, the addition of radar to the vehicle created a potent and cost-effective short-range air defense – ideal for an export market.

Design

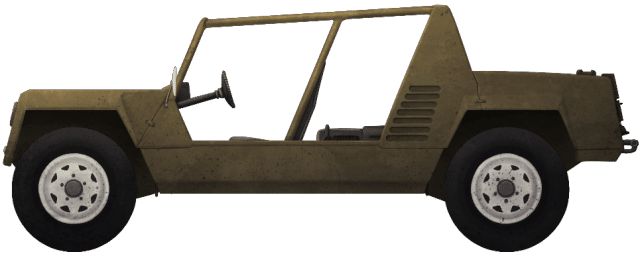

Hull

The hull of the Breda M42 was virtually identical to that of the M42 as it was in service with the US Army. As with a conventional tank, the engine was at the rear, along with the transmission, separated from the crew-space by a fireproof bulkhead. The suspension was provided by means of 5 road wheels attached to torsion bars and with 3 return rollers for the rubber-padded track. Hydraulic shock absorbers were provided on wheel stations 1, 2, and 5, and drive to the track was provided by means of rear sprockets on the tank. The single known drawing for the Breda upgrade shows that the rear is noticeably slightly larger, with the deck going further back on the horizontal and meeting a single angled rear plate meeting the rear lower hull plate. On the original M42 hull, however, the deck sloped back down slightly over the engine, followed by a sharply angled rear section before meeting the rear hull plate. The only logical reason to modify the hull in this way would be to enlarge the bay to create additional space for a larger engine.

Engine

The original US-service M42 had been fitted with a new fuel injection system to the 14.68 liters 500 hp (at 2,400 rpm) AOS-895-3 petrol engine. The vehicle later received the AOSI-895-5, giving a 20% fuel economy increase. With that modification, the M42 was reclassified M42A1 in February 1956 and all M42’s brought up to standard. The Breda upgrade appears to have planned for an improved power plant for this vehicle, as the rear hull shape has been enlarged, although which engine this would have been is not known. It would make sense to plan for improved mobility as, due to the increased weight of the turret, the vehicle would be heavier and thereby less mobile. No changes are known to the existing 530 liter M41 fuel tank, as this was in the hull and there is no information to suggest what changes Breda may have been proposing to the transmission for the vehicle.

Armor

Armor for the Breda M42, was, like on the M42, very light. The all-steel hull was just 12.7 mm thick in most places, enough to protect against small arms fire. The new turret by Breda was, unlike the open-topped original, fully enclosed. The protection was still light, just 9 to 16 mm thick, providing protection from small arms fire and shell splinters and matching the protection level of the hull. The thickest part of the armor was the nose of the tank, at 31 mm thick at 45 degrees, but the front of the turret on this Breda option was a little more sloped than this. 30 mm would be a likely maximum for the front of the turret.

Crew

The driver was seated in the front left of the hull and was provided with a single access hatch on the roof, fitted with an M13 periscope. All of the other four crew members of the M42A1 were situated in the open-topped turret but, for the Breda upgrade, only the driver remained in his original place. The upgrade reduced the turret crew to just two, commander and gunner, each provided with their own cupola on the turret roof fitted with observation devices for all-round observation. The commander, seated on the right of the turret, could also operate the roof-mounted 7.62 mm machine gun. The gunner, on the left of the turret, was in charge of the gun, but both of them were also responsible for reloading it, as ammunition was stowed on both sides within the hull.

Armament

The M42A1 was fitted with a pair of M2A1 40 mm L/56 cannons in a fully rotatable open-topped turret and was provided with hydraulic elevation ranging from -3 to +85 degrees. Each gun was capable of firing 120 rounds per minute out to a maximum altitude of 5,000 m. Used in a ground role, the maximum effective range was 9,475 m.

Ammunition for the M42A1 included the 2.077 kg M81 Series Armour-Piercing-Tracer (AP-T) with a muzzle velocity of 872 m/s, a 2.15 kg High-Explosive-Tracer (HE-T) with a muzzle velocity of 880 m/s, and the 2.14 kg M91 TP-T round with a muzzle velocity of 872 m/s.

Just 480 rounds were carried, meaning there was 2 minutes of firing available for the vehicle.

Gun-laying and sighting were provided for by means of Computing Sight M38, Reflex Sight M24C, and a speed ring sight. Control over the fire was provided by the use of the M38 sight for both air and ground roles, whilst the M24C was there to superimpose a ranging graticule on the gunner’s sight.

The secondary armament consisted of a single 7.62 mm M1919A4 machine gun before the US replaced it with a single 7.62 mm M60 machine gun. This was able to elevate up to 76 degrees at the front and 60 degrees at the rear.

Upgraded by Breda, the vehicle was to use a new single 40 mm L/70 Bofors gun with ammunition stored inside the hull on both sides, a 90-round ready rack next to the gun, and 60 additional rounds on both sides within the turret. With a cyclic rate of 450 rounds per minute, nearly doubling the rate of fire from one gun compared to the twin guns of the M42A1, this single-gun machine provided substantially more firepower. This was a 50% increase on the standard 40 mm L/70 and was the result of modifications by Breda to the gun to improve material quality, use of advanced materials like titanium, improved dimensional thickness, a new and longer recoil buffer to provide greater energy absorption resulting in a shorter stroke (just 100 mm), and a new ramming system for the gun. The ramming system took the shell from the feed-hopper directly to the feeding position on the breech in anticipation of being rammed, cutting the reload time, as the round did not have to travel as far, saving milliseconds in the process.

The development of that gun was based upon the many years of experience in license manufacture of the 40 mm Bofors and this gun-project began prior to 1988 and unveiled that year as the 40L70N ‘Fast Forty’. The gun could still fire standard 40 mm L/70-type ammunition, including armor-piercing (AP), pre-formed fragmentation (PFF) with a proximity fuse, and high explosive (HE). On top of this, it also offered a new 2.3 kg 40 mm Armor Piercing Fin Stabilised Discarding Sabot (APFSDS) round with a 0.2 kg tungsten penetrator for engaging armored ground targets and armored helicopters. The standard HE projectile from this gun had a muzzle velocity of 1,025 m/s. The APFSDS-T was fired at 1,350 m/s.

Two different magazine types were available for the gun, holding up to 120 rounds in the naval installation and obviously a smaller capacity in the ground-based setting. The left-mounted magazine in the drawing held 8 rounds, suggesting it was intended to work as a gun capable of fire in bursts of up to 8 rounds at a time, but allowing for a rapid change from one magazine to another. In this way, in the ground role, the vehicle could potentially offer a burst of either one type of shells or a mixed-magazine of multiple types. These were ideal options for a vehicle capable of engaging both lightly protected airborne targets and armored ground targets.

The turret was still capable, like the old M42A1 turret, of 360 traverse and was powered hydraulically. Although rotation data for the new Breda turret is not available, the original M42A1 turret could rotate at 40 degrees per second. The elevation of the gun was nearly as good as the old system, ranging from -3 to +80. Gun laying for this gun was different too, no longer reliant upon optical sights. Breda offered a variety of options, including an up-to-date surveillance radar on the rear of the turret combined with tracking radar on the turret front.

Conclusion

There was never any serial production of this Breda Upgrade option for the M42. Italy was moving to other options and was not a user of the M42 anyway, as this was an obsolete air defense platform. The upgrade was certainly a competent one, the option to switch between air and ground attack with a weapon able to effectively deal with any target save for a main battle tank, provided a lot of punch for a small and cheap package. In the period at the end of the Cold War, however, the market was simply saturated. Thousands of second-hand vehicles from Germany (in the case of the M42) or the former Soviet bloc were available very cheaply and the sudden lack of a major land adversary for many countries simply rendered this project redundant. The technology Breda developed for the 40 mm gun was not wasted, as it was reused in the ‘fast-forty’ naval gun technology, where it was proven to be both effective and reliable. The M42 upgrade option, for whatever advantages it had, was simply the wrong vehicle and was being offered at the same time as the far more potent and capable OTOMATIC, with a fully automatic 76 mm gun for air/groundwork on the much more reliable and modern Leopard or OF-40-based chassis.

Breda M42 Upgrade |

|

| Dimensions | 5.819 m (hull) Long x 3.225 m wide x >3 m high |

| Total weight | > 22,500 kg |

| Crew | 3 (driver, gunner, commander) |

| Engine | 500 bhp @ 2,800 rpm AOSI-895-5 fuel injected 6 cylinder air cooled supercharged petrol (original) – planned improved power plant unknown |

| Top Road Speed | ~72 km/h (road) |

| Armament | 40 mm Breda improved Bofors L/70 |

| Armor | Hull Front Upper (Glacis): 12.7 mm @ 33 deg. Hull Front Lower: 25.4 mm @ 45 deg. Hull Sides: 12.7 mm @ vertical Hull rear: 12.7 mm Turret: 9 – 16 mm |

Sources

Cullen, T., Foss, C. (1993). Jane’s Land-Based Air Defence 1992-1993. Jane’s Information Group

Cullen, T., Foss, C. (1994). Jane’s Armoured Fighting Vehicle Retrofit Systems 1993-1994. Jane’s Information Group

Pignato, N., Cappellano, F. (2010). Gli Autoveicoli da Combattimento Dell’Esercito Italiano, Stato Maggiore, Rome

Navweaps.com http://www.navweaps.com/Weapons/WNIT_4cm-70_Breda.php

Curami, A., Ferrari, P., Rastelli, A. (2009) Alle origini della Breda Meccanica Bresciana. Fondazione Negri.

Fifth Wheel. (2012). Ed Cole’s Air-Cooled Flat Six. http://www.corvair.org/chapters/lvcc/lvcc_newsletters/lvcc_2012_01_fifth_wheel_redacted.pdf

Italian Republic/United Arab Emirates (1980-1982)

Italian Republic/United Arab Emirates (1980-1982)