United Kingdom (1954)

United Kingdom (1954)

Mine Clearing Flail Tank – Approximately 42 Built

Some of the most important vehicles to hit the beaches of Normandy on D-Day, 6th June 1944, were ‘Hobart’s Funnies’ of the 79th Armoured Division, Royal Engineers. These vehicles – named after the 79th’s Commander, Major-General Percy Hobart – were specialist variants of armored vehicles, all with a specific role to fill. One of the most successful of the ‘Funnies’ was the Sherman Crab.

The Sherman Crab was a mine-clearing variant of the Sherman V (M4A4 to the Americans). It utilized a powerful flail suspended from a frame at the front of the tank. This flail consisted of a large drum with multiple long chains attached to it. Spun at high speed, the chains beat the ground, either blowing up mines where they sat, ripped them from the ground, or beat them into deactivation. The Crab served admirably for the remainder of the Second World War. After the War, however, and with the removal of the Sherman from British Service, designers began to look for a new flail vehicle based on a new, British-built chassis.

Initially, consideration was given to making a flail variant of the FV200 series of universal tanks, then in development as a replacement for the Centurion. However, when the development of the FV200 was canceled, the flail version went with it. As such, designers turned to an old faithful – the Churchill, a heavy and obsolete vehicle available in large numbers, and cheap.

What would emerge from this became known as the FV3902 Churchill Flail, or as it is more commonly known, the ‘Toad’. Entering service in 1954, the Toad featured one of the most powerful mine flails ever created and became one of the last Churchill types to see service – albeit in a training capacity – with the British Army. It is in the Army that the vehicle gained the name ‘Toad’. Quite why is a mystery, although it may just be because it is a rather ugly vehicle – depending on the eye of the beholder, of course.

Development

The Flail tank was originally thought up in 1942 by a South African officer named Capt. Abraham du Toit. The first flail tank to be used by the British Army was the Matilda Scorpion. This consisted of a basic frame carrying the flail drum mounted on the front of the tank. The drum was propelled by a separate engine mounted on the side of the tank. Development of flail tanks would continue to evolve throughout the War, before culminating in the famous Sherman Crab. The Crab was a more advanced, purpose-built variant, compared to the rather haphazard construction of the Matilda Scorpion. The flail was now carried by a purpose-built frame that could elevate or depress as required. The Crab did not require a secondary engine, as the flail was driven by the tank’s own power plant by a power take-off. A key feature of both the Matilda Scorpion and Sherman Crab was that they were to remain combat effective as they kept their turrets and main guns although they would usually have to operate with the turrets reversed in order to prevent damage when ‘flailing’ its way through a minefield.

By 1945, the development of Britain’s next generation of tanks was well underway. Immediately after WW2, the War Office (WO) reviewed the future of the British Army’s tank arm. In 1946, they did away with the ‘A’ designator used on tanks such as the original Churchill (A.22). The ‘A’ number was replaced by the ‘Fighting Vehicle’ or ‘FV’ number. This resulted in vehicles of the Churchill family becoming members of the ‘FV3900’ series. In an attempt to streamline the tank force and cover all the bases, it was decided that the military needed three main families of vehicles: the FV100, the FV200, and FV300 series. The FV100s would be the heaviest, the FV200s would be slightly lighter, and the FV300s would be lightest. All three projects were almost canceled due to the complexity that would’ve been involved in producing the respective series. In the end, both the FV100 and FV300 series were canceled. The FV200 hung on in its development, however, as it was projected that it would eventually replace the Centurion.

Many variants of the FV200 were planned, including gun tanks (such as the FV201, previously known as the A.45), flame throwers, recovery vehicles, and even a flail tank. This vehicle was to be designated FV216 but, unfortunately, there is no indication of what this vehicle would have looked like. In 1949, the FV200 series of common vehicles were canceled in favor of the Centurion, taking the FV216 with it. A few FV200s were built, however, these being the FV214 and FV221 Gun tanks, and the FV219/FV222 recovery vehicles.

The Churchillian Choice

With the cancelation of the FV200, and no plans to convert the Centurion, designers were left wanting. Eventually, they chose to adapt the hull of the Churchill, specifically the Mk.VII. The Churchill Mk.VII was the last big upgrade to the Churchill gun-tanks. Like all Churchills, it was built by Vauxhall Motors, based in Bedfordshire. This version – sometimes termed the ‘heavy Churchill’ or ‘A.42’ – saw the addition of a new turret design and thicker hull armor up to 6 inches (152 mm) thick. It was powered by the same 350 hp Bedford 12-cylinder, 4 stroke, water-cooled, horizontally opposed, petrol engine as all Churchills, which propelled the vehicle to a rather lackluster 15 mph (24 km/h). The Mk.VII used the standard Churchill suspension of individually sprung road wheels with a rear-mounted sprocket wheel. One of the more famous conversions of the Mk.VII was the Crocodile flamethrower tank. It was also the basis of the post-war version of the AVRE, the FV3903.

The Mk.VII was chosen for a few main reasons:

-

- There was a large number of hulls available. Production of the Mk.VII Churchill did not cease until after the Second World War, in October 1945. As a result, large numbers of brand-new tanks were simply lying in storage unused.

- This vehicle would be employed by the Royal Engineers (RE). Thanks to vehicles such as the Churchill AVRE and Churchill ARK, the Engineers were familiar with the type, making driver training and maintenance far easier.

- The Churchill was obsolete. So, rather than carve up the newer front-line Centurion, it made sense to cannibalize an older vehicle. Despite the obsolescence, it must be said that the Crocodile variant of the Churchill did serve in the Korean War.

At a glance, the Churchill may not seem a wise choice for a mine-clearing vehicle. This was due to the position of the driver in the front of the hull and the fact that – during WW2 – the Churchill proved to be vulnerable to mine damage, especially the hull floor. Tests were mounted to assess this by towing a Mk.VII Churchill over mines. The detonations highlighted weaknesses in the weld seams which split open. This fault was dealt with by strengthening and reinforcing the welds. In between and behind the ‘horns’ of the track, the driver had extremely poor visibility. Adding a flail to the front hindered his vision even further due to how low he sat in the hull. This necessitated the raising of the driver’s position, however, this had regressive consequences. One of the most valuable features of both the Scorpion and Crab vehicles was that they retained their turrets and armaments. By raising the Driver’s position – and with it, the superstructure – there was no room for a turret. The tank has now lost its ability to defend itself, or act as a gun-tank when so required.

Another point of regression was down to the Churchill’s lack of horsepower. The Crab made powering the flail unit far less complicated by using a power take-off from its own engine to propel the flail. However, the Churchill’s Bedford ‘twin-six’ 12-cylinder petrol engine was not powerful enough to begin with, without propelling an extra component. As such, like the Scorpion, a secondary engine was to be installed to drive the flail.

With these considerations, a design was finalized as the FV3902. It would end up being one of the most extensive adaptations of the Churchill ever devised. The design of the vehicle would revolve around a large flail assembly suspended from the front of the hull and driven via a secondary engine. Large springs in cylindrical housings were installed on the hull sides to act as a counter-balance for the flail. The secondary engine would be placed behind the 2-man crew compartment at the front of the new armored superstructure. When not in use, and for travel, the flail assembly could be folded back over the superstructure of the vehicle. The rear of the vehicle would also include an automatic safe lane marker system contained in a long box, a relatively advanced feature at the time.

The Cumberland-based Distington Engineering Company was contracted to produce schematics and act as the overseer of the entire project. Two other firms were also brought on; Robinson and Kershaw Ltd. and British Railway Workshops (BRW). Robinson and Kershaw, based in Dukinfield, would be responsible for the modification of the hulls and the fabrication of the new superstructure. BRW, based in Horwich, was responsible for the mechanical equipment and fitting of the flail assembly. Between them, 42 Toads would be built, comprising 2 Prototypes, 6 interim/pre-production models, and 34 service vehicles.

Prototypes and Interim Models

The first FV3902 prototype was completed at the Horwich Works in April 1954. For the most part, this was identical to what would become the production model, however, it did differ in one respect. On this pilot model, a hydraulic system was installed. It was placed in the secondary engine bay and was driven by a take-off from the secondary plant. The hydraulics had three purposes. Firstly, it would power a winch system used to raise and lower the flail boom. Secondly, it would retract the lane marker system at the rear of the vehicle. Lastly, it would power a contouring device that would keep the flail at the same constant height while deployed, no matter how rough the terrain. Prototype 2 followed in about September the same year. This featured a worm-drive for the retraction of the boom and a sensor system for contouring. Both No. 1 and No. 2 prototypes used multiple springs in the counterbalance cylinders on the sides of the hull.

The prototype vehicles were followed by 6 interim, pre-production models built between April and July 1955. The pre-production versions carried some different features to the prototypes, some would be carried over to the production versions, some would not. Retraction equipment for the lane marker system was removed, meaning it would be permanently carried in the deployed position. The same applied to the flail boom. It was still possible to fold the boom back, but this was now a matter of cables and brute force. Inside the counterbalance cylinders, the multiple springs were replaced by single, concentric springs. Another addition was a ‘splash board’ placed across the track ‘horns’ at the front of the tank. This would help to control the amount of debris being thrown up by the flail. Also, fuel for the flail engine was now drawn from a separate fuel tank. An electromagnetic ‘station-keeping’ device was also installed – basically a rudimentary guidance system that would keep the vehicle on a straight path.

Overview of the Production Model

Production models of the FV3902 began to be delivered in January 1956. At 56 long tons* (56.8 tonnes), the Toad was 14 tons (14.22 tonnes) heavier than the standard Mk.VII, and was one of the heaviest of the Churchill-based vehicles. It was even heavier than the Centurion by around 4 tons (4.06 tonnes). As a result of the increased weight, the already slow 15 mph (24 km/h) top speed of the Churchill was reduced to 12.7 mph (20 km/h). The vehicle’s dimensions also changed quite dramatically. While the basic length and width of the hull remained the same at 24 ft 5 in (7.44 m) long and 10 ft 8 in (3.25 m) wide, the new components added a lot of girth. With the addition of the boom arms of the flail, the width increased to 13 ft 6 in (4.11 meters). With the addition of a splashboard between the track ‘horns’ and the lane marker system at the rear, the length increased to 26 ft 3 ½ in (8 meters). With the flail deployed, this jumped to 37 ft 2 ¾ in (11.34 meters). Height wise, the new superstructure increased height to 8 ft 7 in (2.61 meters), only a few inches more than the original 8 ft 2 in (2.49 meters). With the flail in the stowed position, the height jumped to 12 ft 4 in (3.75 in).

*Long tons are an archaic measurement used in the UK – for ease, it will be shortened to ‘ton’. 1 long ton is equal to about 1.01 metric tonnes, or 1.12 US ‘Short’ tons.

The Fastest Flail in the West

The huge flail designed for the FV3902 was, and still is, one of the most powerful chain-flails ever mounted on a vehicle. Equipped on the Toad, it required its own engine. Unlike the Scorpion predecessor, the engine would not be placed outside of the hull, rather it would be built into the new superstructure. The engine chosen was the Rolls-Royce M120 water-cooled, petrol-injection engine, a derivative of the Rolls-Royce Merlin engine famous for powering the British Spitfire and American Mustang fighter aircraft of World War 2. Versions of this engine were also used in the Cromwell, Centurion, and Conqueror tanks, among others. This particular version produced 650 hp, and was placed in the rear of the new superstructure in lengthwise orientation, behind the crew compartment. The clutch and drive end faced towards the front of the tank. The engine bay also housed the fuel and lubrication tanks, as well as the ventilation and air cleaning systems for both engines. Cooling air was drawn in through a large panel of louvers on the rear of the superstructure. After passing over the engine, It was vented through large fan and radiator systems located on the sides of the hull. Access to the engine bay was granted by 4 large, interlocking plates on the roof. Exhaust from the secondary engine was carried along pipes mounted atop the fenders, just above the typical Churchill air-intakes for the Bedford engine (the main engine exhaust pipes remained on the engine deck).

The flail was carried by two large arms, approximately 10 feet (3 meters) in length that were attached to large pivot points on the sides of the hull. Large cylindrical housings placed towards the rear of the hull were placed on the hull sides as well. These were slightly smaller than those of the prototype and interim vehicles and also sat higher to grant better ground clearance. They were still large at around 4 feet (1.2 meters) long and just over a foot (30 cm) in diameter. They were not too dissimilar to the piston housings found on steam locomotives – not a surprise considering the manufacturers. Like the interim vehicles, they contained large concentric springs connected to long rods which were, in turn, connected to the pivot hubs of the flail arms. These acted as counterbalances for the large flail rig. On the production models, the contouring device was removed, meaning there was now no need for the Hydraulics. Instead, the arms would rest on large skids with built-in steel caster wheels. The skids would glide over soft ground while the casters would role on hard surfaces. These casters would also swivel so the vehicle could still pivot with the boom deployed. It was found in tests that even if the skids were blown off by mine detonation, the counterbalance springs were strong enough to keep the boom rigid on their own.

To drive the flail, power would be taken forward from the Rolls-Royce engine via a dog clutch into a bevel gearbox in the nose of the tank, under the crew compartment. The drive passed into the pivot mount of the left boom arm to a second bevel box and driveshaft within the arm. Because of this, the left arm was noticeably thicker than the right. Yet another bevel box was located at the flail hub, which transferred power to a drive shaft that ran the length of the flail drum to an epicyclic reduction final drive at the opposite hub.

The 650 hp engine would revolve the drum clockwise at 150-revolutions per minute. The drum itself was about 11 feet (3.3 meters) wide, about 20 inches (50 cm) in diameter and consisted of two hemispherical halves that were bolted together over rubber drive bands. Sixty eyelets were welded to the drum for attachment of the flail chains. These chains were about 4ft 10 in (1 ½ meter) long and terminated in a large ‘bob’ or ‘element’ weighing 2 ½ lbs (1.13 kgs). These ‘bobs’ consisted of large diamond-shaped clubs on the early vehicles, while simple solid balls would be used on the production models. Rotating at 150 rpm, the chains would be traveling at around 61 ½ mph (99 km/h), meaning each of 2 ½ lbs/1.13 kg ‘bobs’ would be impacting at 5.5 x 10 to the power 9 Joules per strike.

While it was designed to detonate mines, the flail could also be used for light obstacle clearance. The spinning chains would have no trouble tearing through hedgerows (known as ‘bush-bashing’) or barbed wire. On the interim vehicles, cutters, and deflector plates were installed below the boom arms to stop debris – particularly barbed wire – getting caught up in the tracks. These were not installed on the production models as they interfered with the skids. The flail was not to be started unless the vehicle was in motion, otherwise, a large trench would be dug in front of the tank. When flailing, the vehicle moved at just 2 mph (3 km/h). Spare chains would be stowed on the engine deck, at the rear of the vehicle.

When not in use, and for travel, the boom arm had the ability to be folded back over the superstructure of the Toad, where it came to rest on horn-like protrusions emerging from the sides of the secondary engine compartment. The folding of the boom shortened to the overall length of the vehicle by about 10 feet (3 meters). While early versions used either hydraulic or cable systems to mechanically hoist the boom up and back, the production model was devoid of these and as such, and a manual method was employed. Carried on the splashboard were two cables of 50 and 100 feet (15 & 30 meters). These would be attached to an extra eyelet on the flail drum, trailing in front and behind the vehicle. A cable guide placed on the hull roof between the crew hatches was also installed. This was attached as required and was otherwise stowed on the splashboard. Should a friendly tank be available, it was possible for it to physically pull up or lower the boom into the required position. Alternatively, if there was a handy immovable object present – like a tree for instance – the cables could be attached and the vehicle would perform the task itself by slowing moving forwards or backward. Deployable ground anchors were also available for this purpose. A safety lockout was installed to prevent the flail drum spinning in the travel position – for obvious fatally messy reasons.

Lane Marker System

The Churchill Toad was equipped with a sophisticated flag marker system, housed in the large box overhanging the rear of the vehicle. For the time, it was a rather ingenious and complex system, and it was one of the first purpose-built units.

The box housed 59 marker poles on an endless chain. The chain was driven from the left final drive via an external rod. The flags were automatically dispensed every 50 feet (15 meters) with a maximum markable distance of 968 yards (885 meters). The markers were propelled by a .303 caliber blank cartridge at the top of each pole. An automatic hammer in the outer edges of the box fired blank. A long spike would emerge from the compact flag as it was propelled into the ground. The pole then telescoped up, extending to four times its stowed length. The poles were painted red and yellow. If the vehicle was clearing solo, both sides would fire. If two vehicles were operating side by side, the driver could select which side fired, be it left or right. Assuming they could be retrieved, the markers were reusable.

Crew Compartment

The crew compartment was located at the front of the tall new superstructure built atop the front of the Churchill chassis. A large, sloping, 5 ½ inch (140 mm) thick front plate stretched from the bottom of the bow to the compartment roof. This protected the crew compartment from mine explosions or errant flail links and, to a certain degree, enemy gunfire. The splash board was placed roughly midway on the plate, stretching across the track horns. The board was made of thin sheet metal and mounted on a frame, which in turn rested on two long supports rooted to the bottom of the bow. The sloping front plate featured 12 smoke grenade launchers, consisting of 4 banks of 3 tubes. Two banks were angled off to the left, the other two to the right.

A small, two-man crew operated the Toad, consisting of the commander and the driver. Located on the right, the driver’s controls were much the same as the standard Churchill with a few new additions to control the flail, such as a hand throttle and clutch control. He had a single-piece circular hatch above him with padding on the inside. For vision, when ‘buttoned-up’, he had two periscopes that protruded from the compartment roof, just in front of the hatch. Sat to his left was the commander who sat under a derivative of the No. 1 Mk.2 Allround Vision Cupola with 7 pericopes placed around the circumference. The cupola featured a two-piece ‘clam-shell’ style hatch that opened to the left and right. As the circular hatches in the hull sides of the standard Churchill were welded over to make room for the boom pivots, the room hatches were the only way in and out for the two crew members.

Other Details

The vehicle was covered in ample stowage points. Stowage bins covered the outer walls of the superstructure. There were two large bins on the left and right wall, with the rearmost bin double the size of the forward bin. These would be used for both the personal items of the crew, but also for spare chains and other vehicle-related items. Spare track links were carried on the air intakes on the hull sides, while tarps and netting would be bound upon the splashboard. Pioneer tools (shovels, pickaxes) were stowed on the fenders at the rear.

Headlamps were placed on top of the track fenders at the front of the vehicle, just underneath the splashboard. Not the best of locations in hindsight, as these would surely be blown off or damaged during flailing.

Conclusion

At the point the Toad was developed, the Churchill was about 12 years old. Yet the use of the hull proved that the reliability and hard-wearing nature of the vehicle was still valued. Alongside the FV3903 AVRE and the Mk.II ARV – which was also deployed in the Korean War – the Toad would be one of the very last uses of the Churchill tank in the British Army.

The Churchill Toad was posted to units of the Royal Engineers, but would never get a chance to chew up a battlefield in a combat situation. However, it would go on to be used in training exercises. The vehicle was also tested in beach assault scenarios where it would be launched from a landing ship and wade onto the beach. These tests would regularly take place at Instow in North Devon. For the tests, it was equipped with wading extensions to the air intakes. With the intakes fitted, the flail boom could not be retracted, so the vehicle would wade in with it deployed.

During the Cold War, other anti-mine technologies developed during WW2, such as rollers, ploughs, and line charge launchers, continued to evolve, while flails somewhat fell out of favor. Although the Toad was by no means the last of its kind.. Various types of flail vehicles are still in use by militaries around the world today, such as the German M48-based Keiler – developed in the 1970s, and the British Aardvark Area Mine Clearing System (AMCS) – developed in the 1980s. As well as serving in military operations, they are also often used for United Nations land mine clearing missions.

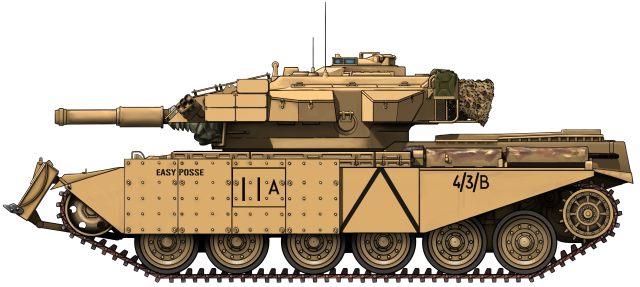

Only one Churchill Toad survives today, ‘35 ZR 10’, with the designation “4A”, and it has been on quite a journey. For many a year, it sat on various Army Bases open to the elements and rotting. Between 2006 and 2008, RR Services in Kent, England began a long process of restoring the vehicle. After an extensive restoration, the now fully operational vehicle was unveiled on 16th May 2008 and demonstrated before an audience. As a safety precaution, the chains were shortened, and the flail was run at half-speed. It was then handed over to the late Jacques Littlefield, of the famous Littlefield Armor Collection or ‘Military Vehicle Technology Foundation (MVTF)’ in Portola Valley, California, USA.

This vehicle was part of the Littlefield Collection until Mr. Littlefield’s untimely death in 2009, after which the collection began to be sold off. On Saturday, July 12, 2014, the Toad was put on the auction block. The winning bid of US$80,500 went to the Australian Armor and Artillery Museum of Cairns, where it continues to stand on display today.

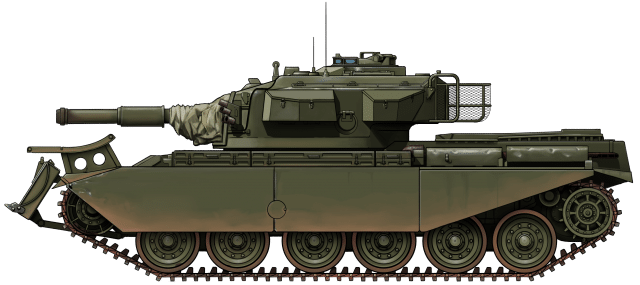

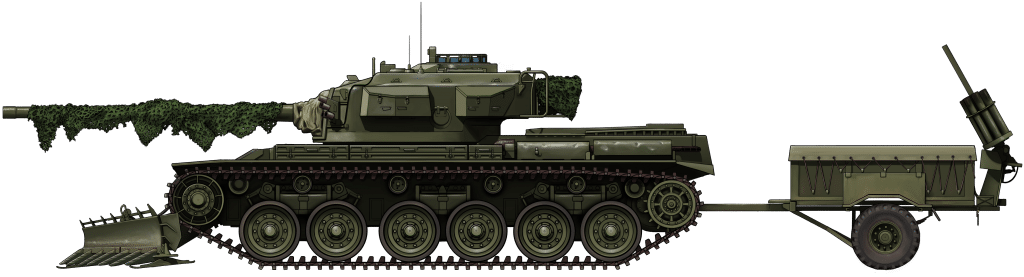

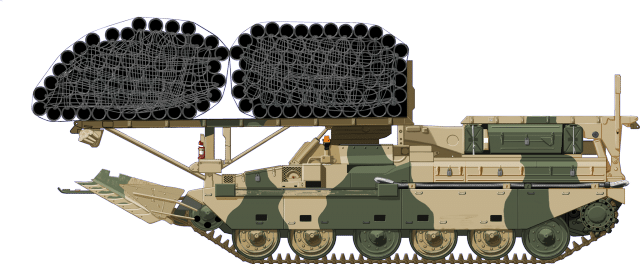

The ‘Toad’ in flailing position. With the boom extended, the vehicle was 37 ft 2 ¾ in (11.34 meters) long. The large spring cylinders support the flail when it is deployed.

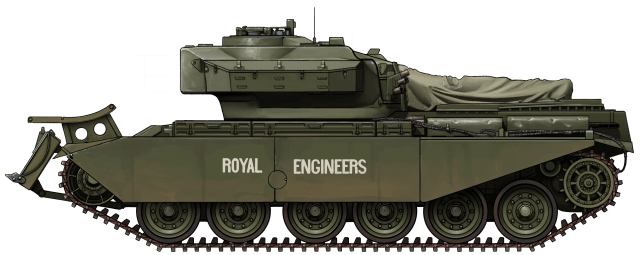

The ‘Toad’ with the flailing drum in the ‘transport’ position. This allows the vehicle to move around relatively unhindered. Although, its 56 long ton* (56.8 tonne) weight did make it very sluggish.

These illustrations were produced by Ardhya Anargha, funded by our Patreon campaign.

Churchill Toad specifications |

|

| Dimensions (L-W-H) | 9.38 x 4.01 x 3.20 m (30’7” x 13’2” x 10’5”) |

| Total weight | 54 tons |

| Crew | 2 (Driver and Commander) |

| Propulsion (Tank) | Bedford twin-six petrol, 350 hp (261 kW) at 2,200 rpm |

| Propulsion (Flail) | Rolls-Royce M120 Meteor, 650hhp at 2400 rpm |

| Speed | 20-km/h (12-mph) |

| Armor | Front: 140 mm (5.5”) Sides: 95 mm (3.75”) |

| Total production | 42 |

Sources

Bryan Perret, New Vanguard #7: Churchill Infantry Tank 1941-51, Osprey Publishing

Wheels & Tracks Issue #20, Article by David Fletcher pages 36-43, April 1987, ISSN 0263-7081

Nigel Montgomery, Churchill Tank 1941-56 (all models), Haynes Publishing

David Lister, The Dark Age of Tanks, Britain’s Lost Armour 1945 – 1970, Pen & Sword Publishing

The Australian Armor and Artillery Museum

Toadman’s Tank Pictures

Details of the Restoration of the Toad on www.milweb.net

Details of the Littlefield auction on Auctions America