United States of America (1944-1945)

United States of America (1944-1945)

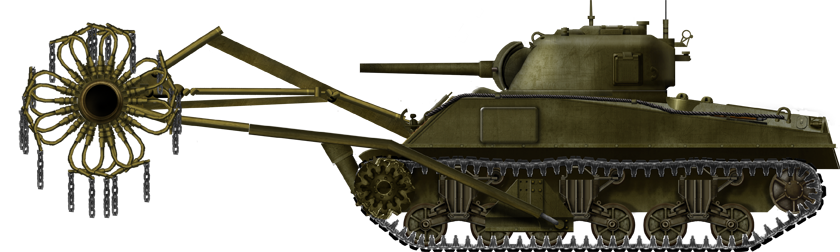

Flail Tank – 1 Built

In 1944, the United States Army began testing British-built flail tanks such as the Crab and Scorpion. Mine flails like these consist of a rotating drum connected to a series of chains suspended from the front of the vehicle. The drum rotates at a high speed, causing the chains to pummel the ground, detonating any mines that may be buried.

Meanwhile, down on Maui, one of the Hawaiian islands in the central Pacific, members of the 4th Marine Division, United States Marine Corps (USMC), were recuperating from their time battling the Japanese on Saipan and Tinian. While on Maui in late 1944, the 4th Marines began to undertake experiments with their tanks, one of which was copying the Crab and Scorpion equipment they had seen in an article in an issue of ‘Armored Force Journal’ (or possibly ‘Infantry Journal’) that the division had received.

The result of this particular experiment was an improvised mine flail built using an old M4 Dozer and the back axle of a truck. While it was just an improvised vehicle built from scrap, it did make it to the ash-covered island of Iwo Jima. Its deployment there, however, did not exactly go to plan.

Guinea Pig, an M4A2 Dozer

The Marine Corps began to receive the M4A2 in 1943. The tank was of a welded construction and was 19 feet 5 inches (5.9 meters) long, 8 feet 7 inches (2.6 meters) wide and 9 feet (2.7 meters) high. It was armed with the typical 75mm Tank Gun M3 main armament. Secondary armament consisted of a coaxial and a bow-mounted Browning M1919 .30 Cal. (7.62mm) machine gun. Armor thickness was pretty standard for the M4s with a maximum of 3.54 inches (90 mm). The tank’s weight of around 35 tons (31.7 tonnes) was supported on a Vertical Volute Spring Suspension (VVSS), with three bogies on each side of the vehicle and two wheels per bogie. The idler wheel was at the rear. Average speed was around 22–30 mph (35–48 km/h). The big difference of the A2 with respect to other M4’s was the fact that it was diesel powered, unlike other models which were mostly petrol/gasoline driven. The A2’s powerplant consisted of a General Motors 6046, which was a twin inline diesel engine producing 375 hp.

Dozer tanks are used for route clearance. Dozer kits were installed on a number of different Sherman types in the Pacific, not just the A2. Others included the M4 Composites and M4A3’s. They were able to push debris off roads or clear routes through the dense jungles of the Pacific islands. The Dozer blade, known as the M1, was 10 feet 4 inches (3.1 meters) wide and was attached via long arms to the second bogie of the suspension. On the transmission housing on the bow of the host tank, a hydraulic ram was placed to allow the blade a small degree of vertical traverse.

The Modifications

After reading the article about the flail tanks the Army had tested, Robert Neiman, the Commander of C Company, 4th Tank Battalion decided that it would be a good idea for the Marines to develop their own version. Nieman discussed this with his Officers and NCOs who agreed with the concept. They knew that, in the coming battles, it was highly likely that they would run into dense Japanese minefields, and there were not always enough engineer personnel to clear them. The guinea pig for this experiment was a salvaged M4A2 dozer tank named “Joker” that had previously served with the 4th Tank Battalion on Saipan. It was available for this experiment as, at this time, the Marine Corps was starting to be re-equipped with the newer gasoline/petrol engined M4A3 model. The modifications were undertaken by Gunnery Sergeant Sam Johnston and Staff-Sergeant Ray Shaw who was also the chief maintenance NCO (Non-Commissioned Officer).

A new welded frame was constructed and attached to the joint on the second bogie. At the end of this frame, they placed a salvaged axle and differential from a truck. Drums were placed where the wheels once were and it was to this that the flail elements were attached. Approximately 15 elements were attached to each drum. The elements consisted of a length of twisted metal cable with towing eyes at the end, short lengths of chain, approximately 5 links in length, were then attached to this cable.

A drive shaft extended from the differential housing to the glacis of the tank and passed through the armor just to the left of the bow machine gun position. On the inside, this meshed with a salvaged transmission from a jeep which was, in turn, connected to the tank’s own drive shaft. This is what provided drive to the flail, allowing it to spin. The bow-gunner/assistant driver would be in charge of controlling the rotation and speed of the flail.

A frame was built atop the vestigial hydraulic ram left over from the tank’s time as a dozer. This frame supported the drive shaft, but also allowed the flail assembly to be lifted up and down. Additional support when lifting was provided by a metal shaft bolted to the glacis of the tank. It had a joint at the glacis end, with the other end connected to the frame near the axle – also jointed.

Testing

On completion of the vehicle, tests were authorized. Division commanders authorized the laying of a live minefield for the vehicle to carve a path through. In this initial test, the vehicle successfully beat a 30 to 40-yard (27 – 36 meter) path through the minefield. The tank emerged unscathed, the only real damage received was to the differential housing. Shrapnel from an exploding mine had penetrated the underside of the housing, but there was no internal damage. To stop this happening again, the engineers encased the housing in welded metal plating and during the following tests, no more damage was received.

Robert Nieman informed other Officers and his superiors of the success of the tests. Pretty soon, a display for high-ranking Officers of other units and branches stationed on Maui was arranged. However, come the morning of the display, the man with all the experience driving the thing, Gy.Sgt Johnston was, to quote Nieman; “drunk as a skunk”. Luckily, another driver was found for the display, which proved to be a great success. So much so, that it was planned to use this improvised vehicle with the 4th Tank Battalion in the coming assault on Iwo Jima.

Iwo Jima

Despite being the only one of its kind (and being a purely improvised vehicle), the flail tank was deployed during the February 1945 invasion of the volcanic island of Iwo Jima. It was assigned to the 4th Tank Battalion’s 2nd Platoon, under the command of a Sergeant Rick Haddix. It caused a small logistical issue, as it was the only Diesel engined tank the 4th Battalion took to Iwo.

Iwo Jima was both the first and last deployment of the vehicle. It is commonly thought that the tank simply bogged down in the soft ashen terrain of the island, as was the case with many tanks during the assault. In actuality, the fate of the vehicle was much more detailed than that. The Flail tank managed to advance to the island’s first airfield – simply identified as ‘Airfield No. 1’. Near the airfield was a series of flags, Sgt. Haddix believed these to be markers for a minefield and ordered the tank forward. These flags, however, were actually range markers for Japanese heavy-mortars in an elevated but hidden position nearby. The tank was pummeled by a barrage of mortar bombs, critically damaging the flail assembly and the tank itself. Following this, Sgt. Haddix and his men bailed out and abandoned the tank.

Conclusion

Thus ends the story of this improvised mine flail. Despite making it to one of the bloodiest battlegrounds of the Pacific Campaign, it never got a chance to prove itself. Robert Nieman was of the opinion that there needed to be more, which would likely have become a reality if American Forces had gone on to invade the Japanese mainland. Nonetheless, this improvised vehicle is a testament to Marine ingenuity. The Marines at this time were used to receiving the Army’s hand-me-downs, so the ‘make do and mend’ nature came naturally to these men. Although, by 1944, the Corps was getting what it requested from its own supply system. It is unclear what happened to the flail tank after it was abandoned. The most logical guess is that it would have been salvaged and scrapped during the post-battle cleanup.

Other US Flails

Neither the United States Army nor Marine Corps ever officially adopted a mine flail, although many were tested; some even in theatres such as Italy. The most produced flail was the Mine Exploder T3, a development of the British Scorpion, built on the hull of the M4A4 – a tank that otherwise went unused in American forces, other than in training units. Just like the Scorpion, the flail assembly was mounted at the front of the tank and was driven by a separate engine mounted externally on the right side of the hull, encased in a protective box. This engine drove the flail to 75 rpm. The Pressed Steel Car Company undertook the production of the T3 and would construct 41 vehicles in total. A number of these were rushed into theatre overseas in 1943. They went on to be used in the Italian Campaign, most notably in the Breakout from Anzio and the fight towards Rome. The flails were operated by men of the 6617th Mine Clearing Company, formed from the 16th Armored Engineers of the 1st Armored Division. The vehicles were eventually declared unfit for service as mine detonations frequently disabled the flail – the flail also limited the tank’s maneuverability.

An improved design for a flail was unveiled in June 1943, designated the T3E1. This vehicle was similar to the British Crab as the flail drum was propelled via a power-take-off from the tank’s engine. Although it was an overall improvement, it was still a failure and disliked by operators. This was mostly because the flail threw rocks and dust into the vision ports and because the flail unit was too rigid to follow the contours of the terrain.

When the Second World War ended, work on mine flails in the US ceased. With the eruption of the Korean War in June 1950, however, attention was again given to such vehicles. In preparation for deployment to the Korean Peninsula, engineers stationed in Japan began working on flails built on late-model M4s, namely the M4A3 (76) HVSS. The most common type to emerge featured wire cutters at each end of the drum, and 72 flail chains. Like the Scorpion flails, the drum was propelled by an external engine mounted in a protective box on the right side of the hull. Other flails were improvised in the field, but information on these is scarce.

Illustration of the Marine Corps’ improvised Mine Flail, built on the hull of a salvaged M4A2 Dozer, using a truck axle and a salvaged transmission from a jeep. Illustration by Tank Encyclopedia’s own David Bocquelet.

Specifications |

|

| Dimensions (not including flail) | 5.84 x 2.62 x 2.74 m 19’2” x 8’7” x 9′ |

| Total weight (flail not included) | 30.3 tons (66,800 lbs) |

| Crew | 5 (commander, driver, co-driver, gunner, loader) |

| Propulsion | Twin General Motors 6046, 375hp |

| Maximum speed | 48 km/h (30 mph) on road |

| Suspensions | Vertical Volute Spring (VVSS) |

| Armament | M3 L/40 75 mm (2.95 in) 2 x (7.62 mm) machine-guns |

| Armor | Maximum 76 mm (3 in) |

Sources

Robert M. Neiman & Kenneth W. Estes, Tanks on the Beaches: A Marine Tanker in the Pacific War, Texas A&M University Press

R. P. Hunnicutt, Sherman – A History of the American Medium Tank, Presidio Press

The Sherman Minutia

Evolution of Marine Tanks

2 replies on “USMC Improvised M4A2 Flail Tank”

A fine article, about an obscure subject (one tank!), but I wouldn’t be me without some comments….

As far as the publication goes, it was probably the Cavalry Journal (which also covered Armor), the predecessor of Armor Magazine. The Infantry counterpart was (depending on the time period), the Journal of the U.S. Infantry Association, Infantry Journal, Mailing List (Infantry School), and Infantry School Quarterly (the name in WW2), before settling on the current name of Infantry in 1959. I can find no reference to an “Armored Force Journal” although one may have existed for a short period 1941-46 as the Cavalry Journal became in Armored Cavalry Journal in 1946Army tank and cavalry units automatically received copies, perhaps the Marines were also on the distribution list or had unit subscriptions.

“3rd Marine Tank Division” did not exist. You’re talking about either the 3rd Marine Division or the 3rd Tank Battalion. Anyway, please consider changing the caption on picture two.

“Shrapnel” is a particular type of ammunition https://en.wikipedia.org/wiki/Shrapnel_shell#World_War_II_era that was virtually obsolete by WW2, a better term might be “fragments”

Department of Redundancy Department – “The Marines at this time were used to receiving the Army’s hand-me-downs at this time” has two “at this times”

Also the sentiment expressed was not true, by late 1944 the USMC was getting what it requested from its supply system. It was nothing but Gyrenes feeling sorry for themselves.

that looks like a rip off of the Sherman crab tank but with improved flails and armor