Republic of South Africa (1995)

Republic of South Africa (1995)

Mine Protected Vehicle / Armored Personnel Carrier – 582 Built

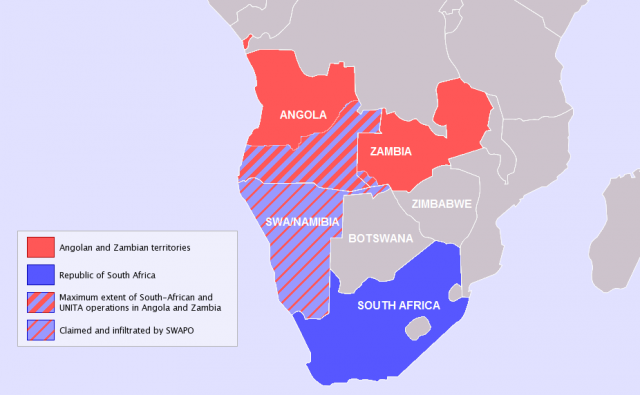

The Mamba Armoured Personnel Carrier (APC) is one of several South African Mine Protected Vehicle (MPV) vehicles that have inspired the modern enclosed V-shaped Mine-Resistant Ambush Protected (MRAP) vehicles used by Western armies today. The Mamba was designed and produced when South Africa was still subject to international arms embargoes (UN Security Council adopted Resolution 418, 1977-1994) due to its segregation policies (Apartheid). This was set against the backdrop of the Cold War in Southern Africa, which saw many anti-colonial wars and internal liberation conflicts along political, ethnic, and tribal lines, supported variously by Eastern and Western benefactors. The Mamba is still widely used as a vehicle of choice for humanitarian and peacekeeping operations by the United Nations and is used by several countries for low intensity conflict operations.

Development

With the South African Border War (1966-1989) still in progress, the rising threat of landmines and Improvised Explosive Devices (IED) and civil unrest brewing in the South African townships, the need for an Armored Personnel Carrier (APC) was identified. This new vehicle had to be capable of operating in an urban environment while still retaining an anti-mine capability. The goal was to develop an affordable mine-protected APC to be used in a defensive role where needed. The Buffel MPV was well suited for the bush but was too vulnerable in an urban setting due to its open tub (troop compartment). Additionally, the Buffel did not provide its occupants with good situational awareness due to its lack of all-round windows. In the background (1988-1994), a debate was raging in the South African Defence Force (SADF), especially in the infantry branch, regarding the suitability of various wheeled configurations such as 4×2, 4×4 or 6×6.

The first Mamba 4×2 variant (Mk1) was developed by MECHEM (MECHanical and ChEMical Research), a subsidiary of the Council for Scientific and Industrial Research (CSIR), which was tasked with the design of concept vehicles for later industrial production. This concept design was done under the leadership of Dr. Vernon Joint and his crew within 60 to 90 days. MECHEM reduced much of the limitations of 4×2 vehicles by placing 60% of the vehicle’s weight on the drive axle in conjunction with specialized Michelin tires. This is claimed to nearly equal a 4×4 design in performance.

MECHEM presented two Mamba APCs categorized as Mk1 to the South African Army for trial and evaluation. The Mamba Mk1 made use of Toyota Dyna 5-tonne driveline and parts. The rationale was to ease logistics as Toyota dealers would have been able to supply parts and services when required making use of off the shelf parts. TFM, an independent company making specialized trucks, was awarded the first industrialization contract in 1987 for around 157 vehicles. Mobility testing was done at various testing facilities and, once accepted by the SADF, the Mamba was tested at the ARMSCORs Gerotech testing facility in 1987. The mine blast testing was done at the Wallmansthal testing grounds.

Due to a dispute between MECHEM and TFM regarding royalties, MECHEM approached OMC Engineering, a Reunert subsidiary, in 1993 for assistance with vehicle production, which subsequently agreed to do so.

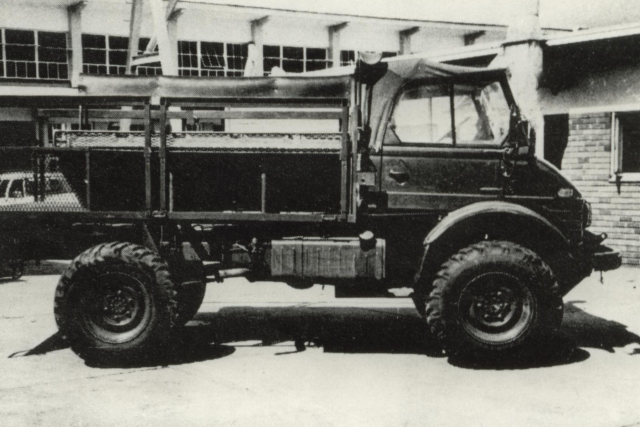

TFM began work on a 4×4 version which it designated RG31. MECHEM found out and immediately set out to produce their own 4×4 version making use of a Buffel Unimog 416-162 drivetrain (left-hand drive) and Mamba Mk1 chassis. MECHEM once again approached OMC/Sandock Austral, which at the time was being reorganized into Reumech (as Reunert had purchased Sandock Austral), for assistance, and the first prototype was produced in just 28 days and designated Mamba 4×4. The vehicle was taken to Gerotech and shown to the chief of the SADF, who immediately asked how many could be built, to which Sandock Austral responded “as many Buffels as you have”. The Mamba 4×4 would, in 1993, cost around R280,000.00 (R 1,370,000 equivalent to US$ 94,462 in 2020), which was just a tenth of the cost of the 6×6 APC Sandock Austral had developed at the time. A request for tender was issued in mid-1994 and ultimately Sandock Austral was awarded the contract. Sandock Austral awarded a contract to Mercedes Benz Trucks to strip the Buffel drivetrain (engine, gearbox, axles, drop down box etc.) to its bare components. These were then evaluated and refurbished where possible to the original manufacturer’s specifications in order for Mercedes Benz to be able to supply replacement parts in the future. The drivetrain was delivered to Sandock Austral which was part of the assembly line.

Preproduction vehicles were all right-hand drive, as driving in South Africa is done on the left side, making left-hand drive vehicles illegal to operate on roads as reduced visibility while overtaking other vehicles can be dangerous. An initial five vehicles were produced and taken on a roadshow around various infantry bases around South Africa to test the concept on all terrains and get user feedback. One of the pre-production Mambas was christened “Modder Varkie” (Mud Piglet) and, together with several other military vehicles, sent on a goodwill tour “Peace for Africa” from July to September 1993 with the end destination set at the BMW factory in Europe. The purpose was to test the vehicles in African conditions and promote the vehicles for possible sales. However, the tour was cut short due to trouble in Central Africa (Burundian Civil War and Republic of the Congo Civil War).

Armaments Company South Africa (ARMSCOR) drew up a list of requirements according to which the Mamba Mk2 would be tested including small arms fire and mine blast resistance. These mine blast tests were conducted on a pre-production vehicle at the Walmansdal testing range, which led to further refinement and improvements in safety that were incorporated into what would become the Mamba Mk2. Around 15 vehicles were produced a month and the South African National Defence Force (SANDF) took delivery of the Mamba Mk2 in 1994.

During testing, Gerotech found that the Mamba Mk2 engine had difficulty during standardized 60 degree Celsius ambient temperature tests which required redeveloping and was subsequently addressed in the Mk3. The Mk3 prototype was ready in 2002 and mine testing was done in the same year. Additional improvements included improved small arms ballistic protection, improved braking and better stability, improved interior layout, and an overall lower operating cost. In 2006, the contract was awarded for 220 Mamba Mk2 vehicles to be upgraded to Mk3 standard under “Project Jury”. These vehicles were delivered in two batches which consisted of 100 and 120. Between 15 and 20 vehicles were completed a month.

A total of 582 Buffel drivelines would be rebuilt to manufacture the Mamba Mk2. The Mamba Mk2 and Mk3 can be found in all branches of the South African National Defence Force (SANDF), and is extensively used by the SA Army. More than 20 other countries have purchased Mamba vehicles, with the UN being the lead customer for use in peacekeeping and demining operations globally. Current and former operators include the African Union (62), Democratic Republic of the Congo (18), Egypt (14), Equatorial Guinea (25), Estonia (7), Guinea (10), Iraq (115), Ivory Coast (10), Niger (6 – Mk7), Nigeria (25), Sierra Leone (5 – Mk5), South Africa (440), Saudi Arabia (25), South Sudan (10 – Reva-3), Sweden (6), Thailand (207 – Reva 3), Uganda (15), United Arab Emirates (56 – Reva), United Nations (17), United Kingdom (6 – Alvis 8) and Yemen (112 – Reva 3).

Design Features

The Mamba Mk2 and Mk3 are designed as all-terrain, all-weather MPVs which can operate in urban and rural areas for long-range patrol and transportation of personnel. The Mamba’s success is due to several key features. It does not have a chassis and the frame sits on the wheels at a height of 410 mm off the ground with a V-shaped armored underbelly which helps disperse and deflect mine blast energy away from the hull, thereby reducing the potential damage. It is of 4×4 design and pneumatically operated differential lock, allowing for effective cross-country use. Making use of commercially available parts reduces its logistical train as spare parts can be supplied easily off the shelf.

Mobility

The Mamba Mk3’s 4×4 configuration was designed for the African battlespace and characterized by its versatility and cross-country capability. It has a ground clearance of 316 mm (12.4 in) and can ford water one meter (3 ft 3 in) deep and can cross a 900 mm-wide (35 in) ditch at a crawl. Its 4×4 configuration allows it to climb a 70% gradient. The Mk2 has a combat weight of 6.8 tonnes and the Mk3 6.2 tonnes. Both the Mk2 and Mk3 are equipped with the Mercedes Benz OM 352, four-stroke 6-cylinder, water-cooled, direct injection diesel engine which produces 123 hp (18.1 hp/t for the Mk2 and 19.8 hp/t for the Mk3). The engine is located at the front of the vehicle and is coupled to a Mercedes Benz UG 2/30, four-speed manual transmission in the Mk2 and eight-speed synchromesh in the Mk3. The driveline has eight forward (four high and four low) and four reverse gears. It can accelerate from 0 to 60 km/h in 25.2 seconds on a level tar road.

The Mk2 was fitted with drum brakes while the Mk3 was improved by fitting disc brakes. The Mamba Mk2 and Mk3 are claimed to be very stable off-road due to the design of the suspension and powertrain. The Mk2 and Mk3 suspension feature a single coil spring on the front axle and double coil spring on the rear which allows for a great degree of deflecting. The four wheels mount 12.5 x 20 Michelin XSL all-terrain tires. Steering is made possible through a hydraulically-assisted recirculating ball.

Endurance and Logistics

The Mamba Mk2 has a 200-liter diesel fuel tank which grants it an operational range of 900 km (599 miles) via road and 450 km (280 miles) cross country. The Mk3 has a 160-litre fuel tank which grants it an operational range of 800 km (497 miles) via road and 400 km (249 miles) cross country. They have a maximum road speed of 102 km/h (64 mph) and can maintain 90 km/h on-road (56 mph) and 25 km/h (16 mph) cross-country.

A modular design and commercial nature of the components ease maintenance and reduce the logistical burden. The Mamba is equipped with a B46 internal radio for tactical communications and has a one-kilometer range. The Mk2 is fitted with a 100-liter fresh water tank and can be accessed via a tap underneath the front left wheel. The Mk3 only has a 50-liter fresh water tank located on the left rear of the vehicle. The Mamba is equipped with a pneumatic tire inflation system. The system is active when the vehicle is idling with positive air pressure available when the vehicle accelerator is pushed down. The exterior storage bins on both sides of the vehicle are used for vehicle equipment, crew and passenger kits, but are not armored. The weight of the Mk3 is less than the Mk2 and was achieved by reducing the number and size of the exterior storage bins. The Mambas lightweight makes it easily air transportable via C-130 airplane.

Vehicle Layout

The Mamba follows a traditional layout with the engine located at the front of the vehicle, driver’s compartment in the center, and troop compartment to the rear. The engine and transmission are protected by the armored hull to reduce the chances of fatal damage if a mine is detonated.

The Mamba has a crew of two that consists of a driver and commander/gunner. The troop compartment can accommodate nine fully equipped soldiers who are seated facing inward in two rows with five seats on the left and four on the right. Each seat is equipped with a four-point safety harness and a weapon’s mount for safe storage. The Mk2 has two large rectangular windows on either side of the hull. The Mk3, on the other hand, has smaller side-facing windows. Access to the driver’s compartment is through the troop compartment rear door which is opened manually. A hinged step below the door allows for easier access. The driver’s compartment has two roof hatches that open to the rear of the vehicle while the troop compartment has six which open to their respective left or right sides of the hull. These hatches can be used as emergency exit points.

Protection

The Mamba is officially designated as a light armored vehicle. It can protect its occupants against a single TM-57 mine blast under the hull or two TM-57 (12 kg TNT equivalent) mine blasts under any wheel. This is achieved by its V-shaped bottom armored monocoque hull design which deflects blast energy and fragments away from the hull. The fuel tank is externally mounted on the right-hand side of the hull and features a blast-proof cap, thereby reducing the chance that mine blasts would cause a secondary explosion as well as minimizing the risk of catastrophic fire to the crew and passengers. The Mk2 and MK3 have a portable fire extinguisher in the driver’s compartment.

The Mk2 hull is rated to protect against 7.62 x 51 mm NATO Ball ammunition. The Mk3 saw an improvement to its ballistic protection level to also include 5.56 x 45mm NATO Ball ammunition at 30 m by adding a layer of fiberglass plates. All windows are bullet-resistant and can protect against multiple 12.7 mm rounds. The Mk2 and Mk3 driver compartment’s left and right window have a firing port each for close-in protection.

The front and rear lights are protected by steel mesh covers. In the center of the roof to the front, protruding upwards, is a wire cutting pole. The purpose is to protect the crew and passengers from wires which could decapitate them while being exposed above the roof hatches.

Firepower

Although not fitted as standard, several barbettes or pintle-mounted weapon systems can be mounted. The weapon system is operated by the commander/gunner through a roof hatch in the driver’s compartment. The pintle mount is fitted to the roof, just forward of the commander’s hatch. An ammunition rack is located on the roof between the commander’s and driver’s hatches. Standard weapons include a 7.62 mm Browning Machine Gun (BMG) or 12.7 mm BMG and 40 mm Automatic Grenade Launcher (AGL).

Operational Doctrine

The Mamba is fielded by all South Africa`s Motorised Infantry Battalions. As a member of the United Nations (UN) and African Union (AU), South Africa is committed to peacekeeping missions in the Democratic Republic of the Congo (DRC), Sudan and South Sudan. The eastern part of the DRC, characterized by mountainous terrain, is plagued by rebel factions that are known for raping, pillaging and murdering civilians and aid workers. The UN Security Council resolution 2098 of 2013 and subsequent resolutions authorized the formation of a Force Intervention Brigade (FIB) in the DRC with a peace enforcement mandate. The FIB consists of three infantry battalions, one artillery and one Special Force and Reconnaissance company. South Africa makes extensive use of the Mamba for their duties as it excels as a quick reaction APC where the predominant threat is small arms fire and mines.

During late May 2019, a Quick Reaction Force (QRF) consisting of a platoon (Charlie Companie) of 7 SAI on rotation as part of the FIB, responded with four Mamba APC`s to an attack on a base at Ngite. While en route, they came under attack from Allied Democratic Forces (ADF) rebels who set up trenches. The lieutenant in command ordered the use of 40 mm AGL to dislodge the ADF rebels from their trenches. While exiting, the ADF rebels crossed the firing line of the Mamba`s mounted 12.7 mm BMG. A total of 23 ADF rebels died in the firefight and a large number of small arms, LMG and mortars with ammunition were recovered.

The Mamba Family

Mamba Mk1

The original 2×4 was produced by TFM Industries (later Reumech OMC) and over 500 were built. It was later modified into the Springbuck Mk1, and the Reva Mk1 by ICP. The Puma is yet another variant powered by a Toyota Dyna 7-145 powerplant and drivetrain, quite common in Africa.

Mamba Mk2

The 4×4 version built by Sandock Austral for the SADF/SANDF and in service with 18 countries. Additional sub-variants includes the Mk2 EE for the Estonian Army, a Mk2 SW for the Swedish Army. The Komanche is a short wheel base (SWB) variant of the standard Mk2 and can accommodate seven soldiers. Some 582 were built for the SANDF. The Sabre had a slightly enlarged driver’s compartment which could accommodate four with a rear cargo bay instead of a passenger compartment.

Mamba Mk3

An up-armored, ergonomically and technically enhanced version of Mk2. Some 220 SANDF Mk2`s where upgraded to Mk3.

Mamba Mk4

The N4 Trucks (Pty) Ltd. company has designed and built a new Mamba designated Mk4 in their Pretoria factory. Blast testing by the Council for Scientific and Industrial Research (CSIR) showed that the Mk4 could withstand the equivalent blast of 10 kg TNT under its hull and 14 kg of TNT under any wheel. It is marketed globally by Osprea Logistics and has been deployed by African Union (AU) peacekeepers in Somalia. Two variants are available, one built on the Magirius air-cooled drive train and the other on an Iveco Eurocargo drive train with a water-cooled configuration. In Iraq, it is used by private security contractors.

Mamba Mk5 IVECO and MAGIRUS

The Mk5 IVECO and MAGIRUS are fitted with an Iveco or Magirus drive train and provides improved ballistic and mine protection, improved performance, mobility and maneuverability compared to its predecessors. It retains all of the well-known design and performance capabilities of the Mamba family and is fitted with the latest improvements and modifications required for the new century.

Mamba Mk6

No material or reference can be found on any Mk6 ever being produced.

Mamba Mk7 OSPREA

The latest version of the Mamba by Osprea is the Mk7 which builds on the success of the Mk5 IVECO and Mk5 MAGIRUS. The Mk7 provides even higher degrees of ballistic and mine-blast protection, excellent mobility, and more maneuverability than its predecessor. The vehicle is built in the United States of America and has more power, provides innovative tactical capacities, advanced technology, upgraded armor protection and makes use of US components.

Conclusion

The Mamba series of APC`s are arguably the trendsetters for the vast majority of MPV`s used today. It has been used by the AU and UN during peacekeeping missions as well as in the Middle East by various countries and military contractors. It can also conceivable that it is the most successful wheeled vehicle design produced to protect armed forces operating in mine-threatened environments in the world. The Mamba range of vehicles have been exported to dozens of countries and saw widespread use in UN, AU peacekeeping, peace enforcement operations in various conflicts. It has been widely copied and at least five types of derivatives are being sold worldwide under licence.

Springbuck Mk1/Mamba Mk1

Mamba Mk2

British Alvis K with IFOR in peacekeeping mission Bosnia 1997

Mamba Mk3

Mamba Mk5

Mamba Mk2 Specifications |

|

| Dimensions (l-w-h) | 5.39 – 2.21 – 2.43 m (17.68 – 7.25 – 7.97 ft) |

| Total weight, battle ready | 6.8 tonnes |

| Crew | 2 + 9 |

| Propulsion | Mercedes Benz OM 352, four stroke 6-cylinder, water cooled diesel engine which produces 123 hp (18.1 hp/t) |

| Suspension | Single coil spring on the front axle and double coil spring on the rear. Additionally it has a hydraulic double-acting telescopic shock absorbers which provide damping for the springs |

| Top Speed On-Road/Off-Road | 102 km/h (64 mph) / 25 km/h (16 mph) |

| Range On-Road/Off-Road | 900 km (599 miles) / 450 km (280 miles) |

| Armament | 7.62 mm BMG 12.7 mm BMG 40 mm AGL |

| Armor | 5 – 6mm (all arcs) armored steel |

| Total Production | +800 |

Mamba Mk3 Specifications |

|

| Dimensions (l-w-h) | 5.46 – 2.1 – 2.5 m (17.91 – 6.88 – 8.20 ft) |

| Total weight, battle ready | 6.2 Tonnes |

| Crew | 2 + 9 |

| Propulsion | Mercedes Benz OM 352, four stroke 6-cylinder, water cooled diesel engine which produces 123 hp (19.8 hp/t) |

| Suspension | Single coil spring on the front axle and double coil spring on the rear. Additionally it has a hydraulic double-acting telescopic shock absorbers which provide damping for the springs |

| Top Speed On-Road/Off-Road | 102 km/h (64 mph) / 25 km/h (16 mph) |

| Range On-Road/Off-Road | 800 km (497 miles) / 400 km (249 miles) |

| Armament | 7.62 mm BMG 12.7 mm BMG 40 mm AGL |

| Armor | 5 – 6mm (all arcs) armored steel |

| Total Production | 220 |

Bibliography

Camp, S. & Heitman, H.R. 2014. Surviving the ride: A pictorial history of South African manufactured mine protected vehicles. Pinetown, South Africa: 30° South Publishers.

DEFENCEWEB. 2019. Mamba could be used by SAMHS as a combat ambulance. Date of access: 15 Dec. 2019.

DEFENCEWEB. 2019. South African soldiers repulse ADF rebels in DRC firefight. Date of access: 16 Dec. 2019.

De Villiers, A. 2019. Telephone interview. Former engineer at Sandock Austral Engineering: Mamba develop and production. Date 2 Dec. 2019.

Gardner, D. 2019. Telephone interview. Former Director OMC Engineering: Mamba develop and production. Date 25 Nov. 2019.

Mabulani. 2018. Personal interview: 21SAI Battalion at Mamba display at the African Aerospace and Defence 2018. Date 21 Sep. 2019.

OPSREA. 2019. Mamba Mk7.

OPSREA. 2019. Mamba Mk5 Iveco.

Potgieter, M. 2019. Telephone interview. Former ARMSCOR project manager: Mamba Mk3. Date 4 Dec. 2019.

RVF. 2019. Armored Vehicle Market Report 2019. Mamba numbers. Date of access: 15 Dec. 2019.

SA ARMY. 2010. Vehicles: Mamba. Date of access: 7 Dec. 2019.

SA ARMY. 2010. Weapon systems infantry: Grenade Launchers. Date of access: 7 Dec. 2019.

SA ARMY. 2010. Weapon systems infantry: Machine Guns

http://www.army.mil.za/equipment/weaponsystems/infantry/Machine_Guns.htm Date of access: 7 Dec. 2019.

Sishuba. 2018. Personal interview: 21SAI Battalion at Mamba display during African Aerospace and Defense 2018. Date 21 Sep. 2019.

WORLD HERITAGE ENCYCLOPEDIA. 2019. Mamba APC. Date of access: 7 Dec. 2019.