Republic of South Africa (1977)

Republic of South Africa (1977)

Mine Protected Vehicle / Armored Personnel Carrier – 2,985 Built

“Buffel” The African Buffalo

After the Hippo APC, the Buffel was the second-ever mass-produced V-shaped hull, open-topped, Mine Protected Vehicle (MPV) / Armored Personnel Carrier (APC). It was made and used by the South African Defense Force (SADF) at a time when South Africa was subject to ever more strict international embargoes because of its segregation policies (Apartheid). This was set against the backdrop of the Cold War in Southern Africa, which saw many anti-colonial wars and internal liberation conflicts along political, ethnic, and tribal lines, supported by often competing Eastern and Western benefactors. The Buffel would become a staple vehicle for SADF motorized units in South West Africa (SWA), where it was primarily used for patrol duties along the Caprivi Strip along the northern border with Angola and Counter-Insurgency (COIN) operations. It was designed to be mobile and provide protection against anti-tank mines, small arms fire, and shrapnel. The Buffel was phased out of frontline SADF service during the late 1980s and was relegated to internal security use until the Mamba APC replaced it in 1995.

Development

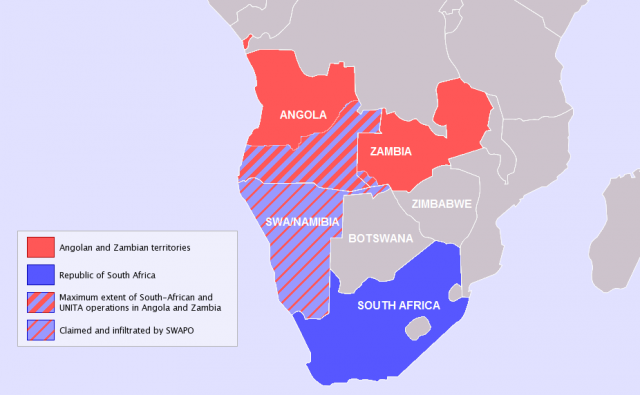

From 1973 onwards, there was a sharp increase in landmine usage by the “South West Africa People’s Organization” (SWAPO), which was fighting an insurgency against South Africa for the independence of SWA. SWAPO operated from bases inside Angola and crossed SWA border over the Caprivi Strip. The SADF at that time had no dedicated mass-produced border-patrol MPV/APC which could protect the occupants against anti-personnel and anti-tank landmines.

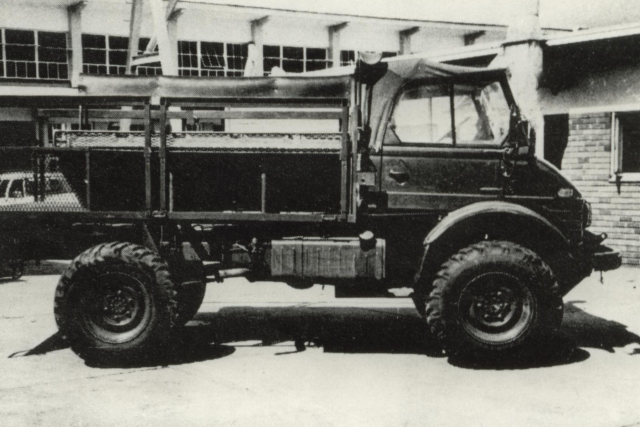

Given the increased threat from landmines, the Defence Research Unit (DRU) was tasked by the SADF with improving the crew survivability of its Unimog fleet. The SADF made use of Mercedes-Benz Unimog S trucks, which they bought during the 1960s, of which 200 were upgraded by Messrs United Car and Diesel Distributors (UCDD) during 1973/4 with more powerful OM352 6-cylinder water-cooled diesel engines. The improvement program resulted in the Bosvark (Bushpig).

The Bosvark featured a V-shaped rear tub which replaced the standard seat section, whilst the driver’s frontal cab section received a Barber deflection plate (mine detonation blast deflection plates). These improvements, while successful, did not protect the occupants from small arms fire. A total of 56 vehicles were produced and used successfully during Operation Savannah (1976). Operation Savannah was the first major military incursion into Angola by the SADF in support of the National Union for the Total Independence of Angola (UNITA), which was fighting a war against the Cuban and Soviet-backed Popular Movement for the Liberation of Angola (MPLA) and the Angolan conventional army, the People’s Armed Forces of Liberation of Angola (FAPLA), for control of Angola.

Post-Operation Savannah, the SADF conducted a needs assessment of their entire fleet. This would later lead to the SAMIL (South African MILitary) range of vehicles. These were specifically designed for the Southern African battle space, requiring long travel distances without logistical support and in which the terrain could damage the vehicle.

Messrs UCDD, who upgraded the Unimogs, came to hear of the new developments and feared a loss in future military contracts. Thus, they set out to redevelop the Bosvark into a dedicated MPV which would function as an APC. Under the leadership of Koos de Wet, who worked at Messrs UCDD, the Bosvark II would take shape. Several improvements were identified and a presentation was made to ARMSCOR early in 1976. A wooden mockup was completed by April 1976 and presented to officials from SADF, ARMSCOR, the Board of Trade and Industry, and the DRU.

ARMSCOR, with the development of the SAMIL range of vehicles, was planning to phase out the Unimog. Subsequent assistance from ARMSCOR for the Bosvark II dried up and the development team had to rely on their own wit and assistance from the DRU to pull the project through. The final prototype was ready by late August 1976, when it presented to ARMSCOR who quickly lost interest and left the demonstration when it came to light that the Bosvark II was not tested.

Despite this, Messrs UCDD continued its support for the Bosvark II, and via contacts in the SADF and DRU, the necessary tests were arranged on a farm near Zeerust. Representatives from interested groups attended and put the Bosvark II through its paces from dusk until dawn. Some improvements were identified by the development team, but the Bosvark II was certified as tested. Nine more test vehicles were built and delivered to the SADF for testing in the then Northern Transvaal and Ovamboland. A quotation was requested for more vehicles from UCDD. The Defence Research Council (later Chemical Defence Unit) of the Council for Scientific and Industrial Research (CSIR), led by Dr. Vernon Joynt, made further improvements.

In 1976, a live blast test was arranged and Koos de Wet was invited to attend to witness the proceedings. Explosives were placed under the front left wheel of the vehicle. In place of a human occupant, an unlucky male baboon was drafted for SADF service, drugged, and strapped into the driver’s seat. After a massive explosion, the vehicle’s left wheel was nowhere to be found. The baboon survived and was given first aid for a cut on its lip. Whether the baboon received a medal for his bravery is unknown. Attendees were impressed and the experts agreed that the driver and passengers would survive a mine detonation. Koos de Wet was informed that the vehicle would be called the Buffel (Buffalo) if it were placed in SADF service. Both Messrs Busaf Border and Messrs Transverse, which contributed to the development, were excluded by the SADF and ARMSCOR from the Buffel production with no compensation given. Further tests were conducted by the SADF and ARMSCOR throughout early to mid-1977 and improvements made.

61 Base General Workshop (BGW) was often called upon to assist in projects and even at times to manufacture and develop prototypes. 61 BGW would become responsible for the disassembly of the SADF Unimog fleet and preparation for its conversion to the Buffel. The first 19 Buffels left Voortrekkerhoogte in Pretoria, South Africa for the major military logistics and supply base at Grootfontein in SWA during the latter half of 1977. The first Buffels were deployed operationally by late 1978, and some 2985 vehicles would be built over 17 years.

The Buffel Mk1 was fitted with the same Mercedes Benz OM352 6-cylinder water-cooled diesel engine as had been used on the Unimog-based Bosvarks and received a bush guard on the front of the vehicle, which helped protect it from damage caused by driving through the bush. The Mk1A was improved by being equipped with drum brakes and an Atlantis Diesel OM352 6-cylinder water-cooled engine (a licensed copy of the Mercedes Benz engine). The Mk1B and subsequent variants used the same licensed engine and had the drum brakes replaced with disc brakes. The Buffel Mk2 saw the passenger tub being redesigned to feature all-round visibility through bullet-resistant windows, an armored roof, and a rear entry and exit door.

The Buffel would come to serve in virtually all the branches of the SADF until its retirement in 1995. The only country to ever buy Buffels from South African government directly was Sri Lanka (185). All other users bought them through private sector auctions or the United Nations. Only a handful of countries still use the Buffel (or variants thereof), which include Malawi, Sri Lanka, Uganda, and Zambia.

Design features

The Buffel was designed to maximize its occupants’ chances of survival when a mine was detonated anywhere under the hull. This was achieved through several key design elements, including high ground clearance, a V-shaped underbelly, and a purpose-built strengthened design that reduced the risk of shattered or buckled hull plates becoming debris.

The African terrain, which in and of itself can inflict severe punishment on a vehicle, necessitates a robust design. The Buffel’s design and simplicity made field repairs post-mine detonation possible. Most parts could be obtained commercially, which made the Buffel’s logistical train shorter and specialized maintenance support in the field unnecessary. The front of the vehicle was strengthened with a bush guard for driving through instead of around small trees and heavy brush, popularly referred to as bundu bashing (bush breaking ability).

Mobility

The Buffel’s 4×4 configuration was designed specifically with the African battlespace in mind, which necessitated excellent cross-country mobility. Being wheeled, also required less maintenance than a tracked vehicle. The suspension consisted of a single-coil spring on the front wheels and double coil springs on the rear wheels. The Buffel had a ground clearance of 420 mm (16.5 in) and could ford 1 meter (3 ft 3 in) of water. The high ground clearance and small width made the Buffel somewhat top-heavy, which occasionally caused problems for inexperienced drivers who would roll the vehicle over if they turned too sharply while at speed, or on uneven or wet and slippery terrain. For those not used to the vehicle’s sway and motion, the passenger tub would be nicknamed the “kots koets” (vomit carriage).

The engine produced 125 hp (20.4 hp/t) at 2800 rpm and was coupled to an eight-speed (eight forward and four reverse) synchromesh manual transmission, the transfer box of which was integrated with the gearbox. The transmission design allowed for in-motion changing between 2×4 and 4×4 wheel drive and featured an equal 50% front and rear axle power distribution. The four wheels were 12.50 x 20 in size. They were often filled with water to help absorb the explosive force from a landmine. Conversely, this added around 1.2 tons of weight which negatively affected the vehicle’s range but helped make it more stable to a small degree.

Endurance and logistics

The Buffel had a 200-liter fuel tank which granted it an operational range of 1000 km (600 miles) via road and 500 km (300 miles) cross country. Its maximum road speed was 96 km/h (60 mph) and 30 km/h (19 mph) cross country. A modular design allowed for easier maintenance and reduced logistical requirements. Additionally, the commercial nature of the components made replacement easy and lowered the cost of parts.

Vehicle layout

The Buffel consisted of three main parts: chassis, armored driver’s cab at the front left of the vehicle, and an armored passenger tub at the center rear. The engine was located on the front right-hand side of the vehicle and the transmission in-between the engine and the armored driver’s cab. The engine and transmission placement facilitated easy replacement in the event of damage due to a mine detonation.

The driver’s cab was surrounded by three rectangular bullet-resistant glass windows and an open-topped roof. The base was wedge-shaped and secured to the chassis via a cable. Early models had no door on the left-hand side, which required the driver to enter through the open-top roof. A single door would be installed on the left side of the driver’s cab to breach this shortcoming and two steel steps. Later variants would also receive a high-density polyethylene roof cover over the driver’s cab. The gear selection was located on the driver’s right side, and a spare wheel was kept to the right of the driver’s cab. The driver’s and passenger’s seating was blast resistant and designed to protect the user’s spine in case of a mine detonation under the vehicle.

Access to the passenger tub was gained via two incremental pairs of steel steps on either side. The passenger tub seating was arranged in two rows of five seats, facing outward from the center. All seats were equipped with harnesses to secure the occupants in the case of a mine detonation or accidental rollover, which would otherwise see them thrown clear of the vehicle. A further feature was an anti-roll bar over the top of the passenger tub, which would stop the passenger tub from rolling over completely. The left and right sides of the passenger tub contained a horizontal panel with circular grooves to allow rifle fire from the passenger’s seating. During contact, the passengers would debus by jumping over the side of the vehicle. The panels were horizontally hinged, allowing them to be opened to ease disembarking. However, this was rarely done while on the move, as the panels tended to flip back up while crossing uneven terrain at speed, which could lead to injury.

Traditionally, the section leader would sit on the front left to facilitate communication with the driver. The section machine gun team sat at the rear left with the second-in-command (2IC), who operated the rear-facing machine gun. The number one rifleman sat in the front right and manned the front-facing machine gun, while the remainder of the section sat on the right.

On the rear of the passenger tub is a sizable storage box. The passengers used the front to store spare kits, while the top was for the driver’s use. Occasionally, a road-killed warthog would be thrown in the storage box for later consumption. At the rear of the chassis was a water tap that was connected to a 100-liter freshwater tank.

Protection

The Buffel could protect its occupants against a single TM-57 anti-tank mine blast under the hull, which was equivalent to 6.34 kg of TNT, or a double TM-57 anti-tank mine blast under any wheel. Its V-shaped bottom armored hull design deflected blast energy and fragments away from the driver and passenger tub. The driver’s cab windows were all bulletproof (bulletproof is a misnomer, and should rather be called bullet-resistant). A plastic fuel and water tank was located above the V-shaped underbelly of the passenger tub, to the rear. These tanks would help absorb explosive blast energy from a mine detonation. The armored driver’s cab and passenger tub protected against common small arms fire in theater, which included 7.62 x 51mm NATO and 7.62 x 39mm AK-47 Ball as well as explosive fragments.

Firepower

The Buffel’s standard armament was either a single or dual pintle-mounted 5.56 mm or 7.62 mm Light Machine Guns (LMG), which were located on the forward right-hand side of the passenger tub and/or rear left-hand side. Twin mountings have also been observed, with the gunners receiving a gun shield as well. In open terrain, this placement was convenient, but when the Buffel entered the thick bush, the primary armament being located forward would get turned around by branches, making their effective use difficult.

THE BUFFEL FAMILY

The Buffel spawned several variants, which include a 2.5-ton Cargo Carrier and an Ambulance.

Cargo Carrier

Based on the Buffel Mk1B, the Cargo Carrier was produced in the early 1980s. It retained the one-man driver’s cab, however, the personnel tub was replaced with an open load bed. It could carry 2.6 tons of cargo over 900 km. A total of 57 were produced.

Ambulance

Using the standard Buffel Mk1B, the Ambulance variant prototype retained the armored one-man driver’s cab at the front. The passenger tub was redeveloped to be enclosed and could accommodate two medical staff, four lying and one sitting patient. Access was gained to the passenger tub via a rear door. It was, however, concluded that the swaying motion of the passenger cab would make the treatment of casualties difficult and very uncomfortable. Subsequently, no orders were placed.

Moffel

When the Buffel was deployed in urban operations to quell the ever-increasing civil unrest and factional fighting (1991-1993) in South Africa, a redesign was needed to improve all-round safety. This involved enclosing the driver’s cab and passenger tub, which were vulnerable to petrol bombs and other dangerous flying objects. The passenger tub’s horizontal drop-down panels were replaced with bullet-resistant glass windows with two firing ports each. A rear access door with a bullet-resistant window was added to facilitate entry and exit from the tub. Additionally, a bullet-resistant window was fitted on the forward right side. The passengers could open hatches on the top of the cab. The subsequent redesign of the passenger tub reduced the available space from ten to eight passengers and the seating faced inwards. The overall improvements allowed better all-round visibility while vastly improving the safety of the passengers. The Moffel was not produced in great numbers, as the Mamba APC was already being developed.

One reply on “Buffel APC/MPV”

I am a model builder and wonder if it is possible that you can help me. I am looking for blueprints for the Buffel. I want to built it because we use to use it on the border.