Commonwealth of Australia (1941)

Commonwealth of Australia (1941)

Cruiser Tank – None Built

The Sentinel that never was

Contrary to a popular misconception the AC II was not a design for the installation of an Ordnance 6 pounder gun in the AC I Sentinel cruiser . Such a design did exist, entitled AC IA, but this is covered more appropriately with the AC III Thunderbolt. In reality the AC II was a simplified design intended to expedite production of the tanks Australia so desperately needed.

Due to the lack of progress by mid-1941, doubts were raised about the practicality of Australia attempting to manufacture such a complex tank design as the AC I. As a result, Australian AFV engineer Alan H Chamberlain proposed a competing design in June of 1941. The proposed design, entitled AC II, was intended to overcome the limitations of Australian industry by substituting the complex M3 drivetrain and gearbox for a commercially available Mack truck gearbox and drive, imported from the USA.

Due to the Mack components not being required for US munitions production it was estimated that deliveries could begin in October of 1941 with series production of the AC II beginning in January of 1942 at a rate of 8 tanks per week. Compared to 5 tanks per week in mid-1942 for the AC I. The Mack components however required a reduction in the weight of the vehicle and were limited in the horsepower that could be used to power the tank. It was alternatively mooted that the Mack gearbox could simply be substituted into the AC I design. However concerns that in a 28 tonne tank the Mack gearbox would be overloaded, risking the gear teeth stripping at low gears, put an end to this idea. As proposed, the AC II weighed 19.5 tonnes with a hull armor basis of 2 ¼ inch (57.15 mm) frontal and 1 inch (25.4 mm) side and rear, and 2 ½ inches (63.5 mm) of all around turret armor.

The intended engine was to either be a twin mounting of the same Cadillac V8 engines used in the AC I or a 225 horsepower GM 6-71 diesel engine. A Curtiss aircraft engine was also investigated but found to be overly powerful for the Mack gearbox and thus unsuitable without substantial modification . Despite the decreased weight, the corresponding decrease in engine power resulted in an estimated top speed of 19 mph (30 km/h). The armament was the same as on the AC I.

Line drawing and armour specifications of AC II. Source: National Archives of Australia MP730/13 14

Unable to meet the Requirement

The Army were concerned by the armor of Chamberlain’s AC II design, arguing that 1 inch (25.4 mm) of side and rear armor was too thin to protect against light anti-tank weapons such as anti-tank rifles and 20 mm (0.79 in) cannon shells. Subsequently, the Army tendered a modified 22 tonne version of the AC II with an increased armor basis of 2 ½ inches (63.5 mm) frontal armor and 1 ¾ inch (44 mm) side and rear armor. However, the increased weight of the modified design was considered to be the absolute limit of the Mack components and the speed had been further reduced to 16 mph (25 km/h).

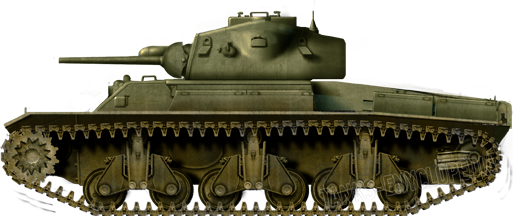

Artist’s rendition of a production AC II

The AC II design was favourably reviewed by Mr Michael Dewar of the British Purchasing Commission, claiming that the design was likely to be the equal of and in some respects superior to the British Valentine Infantry tank. This was small consolation however, as the Army had already rejected the Valentine as too slow and inconsistently armored. The Army would not accept the AC II due to it not meeting the listed top speed requirement of 35 mph (56 km/h). Some consideration was given to increasing the front and side armour to a basis of 3 and 2 1/16 inches (76.2-55mm) respectively and implementing the AC II as an infantry tank with a top speed of roughly 10mph (16 km/h), however this was not further pursued due to lack of army interest in infantry tanks.

For emergency use only

The AC II also caused considerable problems with relations between Australia and the US Lend Lease authorities. From the perspective of US authorities Australia seemed to be wasting resources on pursuing two almost identical designs simultaneously, which made the US reluctant to invest support in the project. Such was the level of hesitance and confusion associated with the AC II that it required Director of AFV Production , Alfred Reginald Code, to travel to the US in late October of 1941 in order to personally expedite deliveries of US parts to Australia and reassure US authorities that Australia only wanted one design of tank.

By October of 1941, no shipments of parts for the AC II had been delivered and initial production was estimated for mid-1942, the same time as the preferred AC I. Consequently consideration was given to producing the AC II as a lead up to AC I production, after which excess production would be exported to allied nations in need of tanks, but this plan was not pursued. After October of 1941, the AC II was only ever considered as a stopgap measure for emergency defence and ultimately did not progress beyond the drawing board.

AC II specifications |

|

| Dimensions | 6.32 x 2.77 x 2.56 m (20’9” x 9’7” x 8’4”) |

| Total weight, battle ready | 22 tons |

| Crew | 5 (commander, loader, gunner, driver, machine gunner) |

| Propulsion | 2 x V8 Cadillac, 220 hp total GM 71 diesel, 225 hp |

| Suspensions | Horizontal volute springs (HVSS) |

| Max speed | 16 mph (25 km/h) |

| Armament | 2-Pounder QF (40 mm/1.57 in), 130 rounds 2x Vickers .303, (7.9 mm) 4250 rounds |

| Armor | 57.16 mm frontal (2.25 in) |

Links and Resources

Australian War Memorial Archives

The AC Sentinel on Wikipedia

Tank Hunter

8 replies on “AC II Cruiser Tank”

Wasn’t it supposed to have a 25-pdr for the main gun?

The AC II had the same armament as the AC I, one 2 pounder main gun and two Vickers machineguns

I think you’re thinking of the 25 pounder armed AC III Thunderbolt, which we’ll be covering in its own article soon to be published

are you also doing the 17-Pounder Variant

We are indeed.

– TE Moderator

I see that from the amount of sherman’s and T-34/T-34-85’s that the US and USSR made we are always going to have some left to show, but what I don’t understand is that for the tanks that we don’t have why don’t we just make more of them?

There are a few reasons for this.

Firstly you have the cost factor, tanks are expensive, even if you cut corners by using mild steel instead of armour you still need to make specialised parts that you can’t just buy from a retailer. Additionally when tanks are being mass produced that offsets the cost, one tank is expensive but many tanks cost less proportionately so its expensive to just make one offs for display purposes

Secondly is plans and blueprints. Just having the picture of the vehicle isn’t enough, you need detailed drawings for all the components to make sure everything fits and works. In theory you can reverse engineer parts that you don’t have drawings for but its more art than science. For instance the above line drawing is the only known picture of the AC II that we have, and its definitely not enough to tell us how the suspension or drivetrain work etc

“1 inch (25.4 mm) of side and read armor”

Didn’t you want to mean “rear armor” instead?

Amended, Thank You.

– TE Moderator