United Kingdom (1944)

United Kingdom (1944)

Beach Armored Recovery Vehicle – 52-66 Built

In the mid-1940s, with amphibious landings becoming ever more prevalent during the Second World War, it became evident to the British that specialized vehicles were required to help clear the way or assist in vehicle recovery. In such a landing, it was important to keep a constant flow of traffic to allow rapid disembarkation from landing craft and the subsequent withdrawal of said craft from the area of operation. This allows the landed units to begin the fight, and continue a constant momentum in the assault.

A prime example of such a landing was looming on the horizon. This was Operation Overlord, the Allied Landings on the beaches of Normandy in 1944; D-Day. These were the largest amphibious landings to have ever been attempted, and the Allies were under no illusion that such vehicles would be necessary during the operation.

These vehicles were given the title of ‘Beach Armoured Recovery Vehicles’ or ‘BARVs’. Initially, the concept was tested with modified Caterpillar D8 Tractors. The main modification was the introduction of a new superstructure with the shape of a ship’s bow. This superstructure was enclosed, and watertight. It allowed the tractor to partially submerge itself in deep waters to pull any stranded vehicles from the beach. These D8s were a relative success, but they were slow, even more so in water. They were also poorly armored.

A BARV pulls a stranded jeep from an LST (Landing Ship Tank). Photo: Panzerserra Bunker

Further tests utilized waterproofed Churchills and Shermans with simple box structures added in place of their turrets. The tests proved that an all-welded hull was the best option as it was simpler to make watertight. For this reason, the Sherman was chosen, at first in the form of the Sherman V (M4A4). Work started on the Sherman V BARV November 1943, and it was fitted with a welded, armored superstructure. An internal air intake for the crew and a bilge pump was added to pump out any water taken on. This prototype proved capable of operating in the 3-meter surf. The vehicles were needed urgently, as such certain features were negated such as a winch and beach-anchors. Therefore all recoveries were in the form of straight pulls.

An order was placed for 50 BARVs, later raised to 66. The production version would be based on the plentiful Sherman III (M4A2).

M4A2, The Sherman III

The M4A2 appeared in 1942 and, like the M4, was of a completely welded construction. The major difference between the A2 and other models of the tank was the GM 6046 twin diesel engine. The tank weighed 32 tons, with the weight supported on a Vertical Volute Spring Suspension (VVSS). Top speed was around 22–30 mph (35–48 km/h). Usual armament consisted of a 75mm gun in the turret, a coaxial and a bow mounted .30 cal machine gun. The tank was manned by a five-man crew; commander, gunner, loader, bow gunner/assistant driver, and driver.

The M4A2 was rarely used by forces of the United States, though a few did see service in the Pacific with US Marines fighting the Japanese. It found a home in the British Army where it was known as the Sherman III. It was also used by the Soviets and the French.

One of the reasons the A2 was chosen for the BARV project was its diesel engine. It was believed that this engine would be less affected by rapidly alternating temperatures due to plunging in and out of the ocean. As discussed above, the welded construction made the hull easier to waterproof.

Design

The design of the BARV was developed by the Experimental Beach Recovery Section of the Corps of Royal Electrical Mechanical Engineers (REME), working with the Mechanical Engineering (ME) Directorate of the War Office. The design replaced the tank’s turret with a large superstructure shaped like a ship’s bow. The superstructure stretched the length of the tank’s hull, right over the engine deck. The structure would allow the BARV to be stable while submerged and allowed it to operate in water up to 9 feet (2.7 meters) deep. A large vent was added at the rear of the structure to allow the escape of exhaust smoke and gases. In front of this was an extendable snorkel. This allowed air into the engine bay to keep it cool and allow it to breathe. When not in use, the snorkel could be retracted so the vehicle wasn’t too tall for transportation.

Two Sherman BARVs and one D8 BARV attempt to recover a stranded Churchill Mk.IV in a training situation on the English coast. Photo: HMSO, Vanguard of Victory: The 79th Armoured Division

The superstructure was armored enough to withstand small arms fire and cannon fire. The best defense, however, was to simply sit the tank in deep water as the amount of the tank exposed would be very small and the water surrounding it would help to shelter it from incoming fire.

On each side of the superstructure, atop the sponsons, heavy-duty wire mesh catwalks were added. The wire mesh allowed water to pass straight through. These reduced the vehicle’s floatation but still to allowed the crew to walk along the length of the vehicle. A folding ladder was attached to the back of the right-hand catwalk to allow the crew to climb up onto the towering vehicle. Ropes were looped through small struts attaching the catwalk to the sponsons to assist crewmen mounting the tank while exiting water.

A BARV towing a small truck up a beach. The commander, standing on the catwalk, is communicating with the driver via a microphone and headset. Photo: Panzerserra Bunker

A winch was deleted from the BARV’s design. Even though the winch would be internal, it was considered too much of a hassle to try and waterproof the winch cable aperture. Because of this, the BARV would have to use brute force alone to tow stranded vehicles off the beach. There was also a large, rope covered wooden buffer block mounted at the front of the hull. This was used to shunt landing craft back out to sea, or assist in pushing other vehicles up the beach if they were having trouble finding traction. Shunting is also faster and does not require a crewman to exit the vehicle.

Visibility was poor for the driver who had only a glass vision port to look through, and in deep water, it was next to useless. The commander had a hatch at the top from which he would guide the driver. It was recommended that in hostile situations the commander navigate ‘under-armor’, but as with other tanks, the BARV’s commanders operated mostly head out. Being quite high up, this gave him better vision all around although he was exposed to enemy fire in doing so.

Three of the BARVs crew members ride atop their vehicle as it passes Sherman Tanks of the 13th/18th Royal Hussars, during that regiment’s move from Petworth to Gosport in preparation for D-Day. Photo: Panzerserra Bunker

Crew

The BARVs had a unique crew make up of men from the Royal Engineers which included a trained diver. Equipped with breathing apparatus, it was his job to attach tow lines to submerged vehicles. It was a five-man crew including the diver, the other crewmen being the commander, driver and two mechanical engineers. These members of the crew also had access to the breathing apparatus.

Operation

Diver Assisted Recovery: The BARV would reverse up to the front of the stranded tank. Before diving, to reduce buoyancy, the diver would enter the water and open a small valve in his sleeve, allowing water pressure to push air out through it. He would then climb aboard the vehicle once more to attach his lifeline and put on his breathing mask and goggles.

The diver then went overboard, taking a tow line with him. The tow line was then attached to any of the towing shackles at the front of the stranded vehicle. Once the diver returned aboard the BARV, a brute force tug got the stranded tank to shore.

Clearing LST Launch Ramps: A tank getting stuck at the end of a launch ramp of an LST (Landing Ship Tank) would hold up the disembarkation of following vehicles. A BARV, following signals from the stranded tank commander, would approach backward. A tow line would then be attached. A good deal of slack was granted, with the BARV moving about 10 meters away from the stranded tank. This was to avoid the stranded tank suddenly rolling down the ramp and rear-ending the BARV. Once ready, the slack would be taken up, and the BARV would pull the tank up the beach.

Shunting: Should a tank be having trouble getting up the beach, the BARV would approach from the rear and use its wooden buffer block to push the tank up the beach. As mentioned above, the block was also used to push off empty landing crafts that have become beached.

The Wooden blocks on the Front of the BARV at the D-Day Story in Portsmouth, UK. Photo: Author’s own

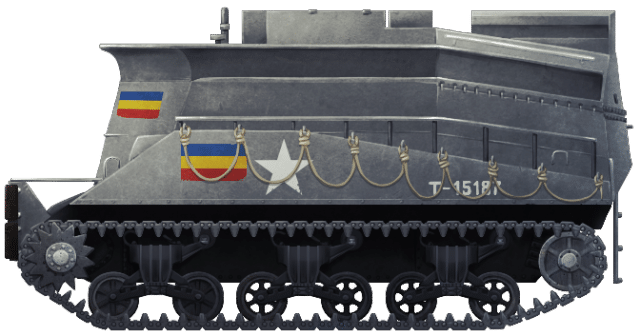

The Sherman III (M4A2) based Beach Armoured Recovery Vehicle (BARV). The blue, yellow and red tri-colour flag is that of the Royal Electrical Mechanical Engineers (REME). Illustration by Andrei ‘Octo10’ Kirushkin, funded by our Patreon Campaign.

Service

The BARV is often referred to as one of ‘Hobart’s Funnies’. However, this is not strictly correct as Major General Percy Hobart was not involved in the project, and it did not serve in his famous 79th Armoured Division. It is a ‘Funny’, as in a strange looking vehicle with a unique purpose, but it is no one of Hobart’s.

One of the D8 BARVs in Normandy, 1944. A Sherman BARV can be seen operating in the background. Photo: Panzerserra Bunker

Around 52 BARVs were deployed on D-Day, providing crucial assistance in getting vehicles on and off the assaulted beaches. The BARVs, along with tractors and wheeled recovery vehicles formed REME Beach Recovery Sections. These were some of the first units of the beach. It is known that at least one BARV was used to carry two motorcycles onto shore. These were attached to the side of the vehicle’s superstructure.

After the landings, they were kept in reserve, helping out at pop-up harbors and landing sites. They did serve in action once more during the war, however, being called on to assist in the Rhine crossings of March 1945.

Panzerserra Bunker

The Sherman BARVs remained in service well into the 1950s. By this time, it was becoming clear that the old Sherman was having trouble towing the heavier landing craft and vehicles coming into service. Work on a replacement would begin in 1956/57. The replacement was based on the ever reliable FV4200 Centurion tank, specifically the Mk.3 version. This new BARV would enter service in 1963, fully replacing the Shermans.

Other Nation’s BARVs

Australia

Seeing the success of the British Sherman BARV, the Australians began developing their own version based on the M3A5 Grant, upgraded with the M4 Sherman’s VVSS suspension. It was equipped with all the same equipment, including the ‘ship’s bow’ superstructure, wooden buffer block, and towing ropes.

The vehicle was designated the ‘Beach Armoured Recovery Vehicle (AUST) No.1 Mark 1’ (AUST for Australia). It had a shallower operating depth than the Sherman, only able operate in up to 2 meters of water with a 1-meter swell. Just one of these conversions was produced, and it served up to 1970. The vehicle survives today, and is on display at the Army Tank Museum, Puckapunyal.

Australia’s Grant BARV, on display at the Army Tank Museum. Photo: Wikimedia

Canada

The Canadian Military attempted to create a BARV on the hull of their Ram Cruiser Tank. The asymmetrical cast hull of the Ram made it hard to completely waterproof. As such, only one prototype was created, and it does not seem to survive today.

Canada’s Ram BARV. Photo: Panzerserra Bunker

Survivors

A number of these unique Sherman modifications do survive. Perhaps the best example can be found at the ‘D-Day Story’ Museum in Portsmouth, UK. Another can be found in the Royal Electrical Mechanical Engineers (REME) Museum in Wiltshire, UK. One is also in the private collection of military vehicle restorer Rex Cadman. It is in running condition, and often even takes part in amphibious demonstrations. A slightly less fortunate example can be found as a rusting hulk outside the Tank Museum, Bovington, near the car park. This was an ex-range target from Salisbury Plain. One more BARV can be found as far afield as India, at the Cavalry Tank museum, Maharashtra.

Sherman BARV ‘Vera’ at the D-Day Story Museum in Portsmouth, UK. Looking at casting marks on the hull, it appears this BARV was converted from an M4A2, and is a Pullman Standard. The tread plate attached between the wooden buffers and hull is a post war addition. Photo: Author’s own

Rex Cadman’s running BARV in an amphibious demonstration. Photo: Rex Cadman

Sherman specifications |

|

| Dimensions | 5.84 x 2.62 x Aprx 3 m 19’2” x 8’7” x Aprx 10′ |

| Total weight, battle ready | 30.3 tons (66,800 lbs) |

| Crew | 5-6 (commander, driver, co-driver, diver, 2x mechanics) |

| Propulsion | General Motors 6046 twin inline diesel engine, 375 hp |

| Maximum speed | 48 km/h (30 mph) on road |

| Suspensions | Vertical Volute Spring (VVSS) |

| Armor | Maximum 76 mm (3 in) |

Links & Resources

Presidio Press, Sherman: A History of the American Medium Tank, R.P. Hunnicutt

Haynes Owners Workshop Manuals, Sherman Tank, 1941 Onwards (all models), Pat Ware

David Fletcher, Vanguard of Victory: The 79th Armoured Division, Her Majesty’s Stationery Office

Panzerserra Bunker

worldwar2headquarters.com

REME Museum

anzacsteel.hobbyvista.com

“Tank-It” Shirt

Chill with this cool Sherman shirt. A portion of the proceeds from this purchase will support Tank Encyclopedia, a military history research project.

American M4 Sherman Tank – Tank Encyclopedia Support Shirt

Give ’em a pounding with your Sherman coming through! A portion of the proceeds from this purchase will support Tank Encyclopedia, a military history research project.

9 replies on “Sherman BARV”

I think the crew description inside the info box is mistaken, as far as I know there is no gun to shoot/load.

Fixed, thank you.

– Author

> a bilge pump was added to eliminate the intake of water.

A bilge pump removes water which has entered, it doesn’t prevent it entering.

> The structure would allow the BARV to be stable while submerged

Partially submerged…

> and allowed it to operate in water up to 9 meters deep

9 feet.

The full name of REME should be listed as the “Corps of Royal Electrical and Mechanical Engineers”

The engine listed in the Sherman specifications box is wrong – the BARV had the GM 6046 twin diesel engine.

All fixed, thank you.

– Author

Great article and photos! Thanks mark

There was at least one in service in the post war french army. Photo on the “char français” website.

http://www.chars-francais.net/2015/index.php/liste-chronologique/de-1945-a-1990?task=view&id=1576